- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com

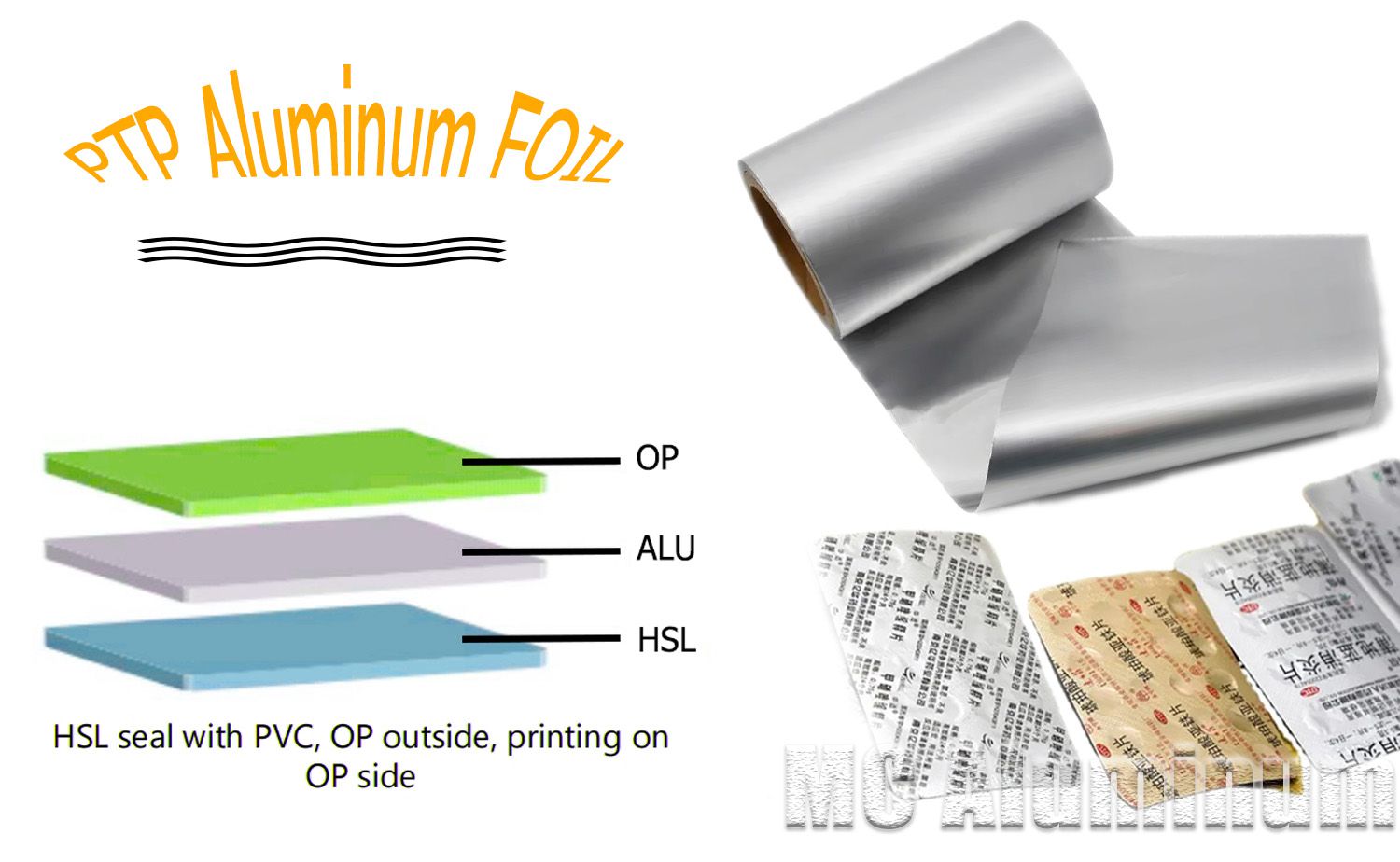

PTP Aluminum foil

Alloy:1100, 1200, 1235, 1145, 3003, 8006, 8011, 8011A, 8079

Thickness:0.024-0.030 mm

Width:80-1000mm

Coiling diameter:275-500mm

PTP aluminum foil, also known as blister foil or push-on lid foil, is mainly used for heat sealing with PVC, PVDC, PP for medicines in blister packaging process, such as capsules, tablets, pills, etc.

The basic composition of PTP aluminum foil is protective layer (OP)/printing ink/aluminum foil substrate (MC aluminum product)/adhesive (VC).

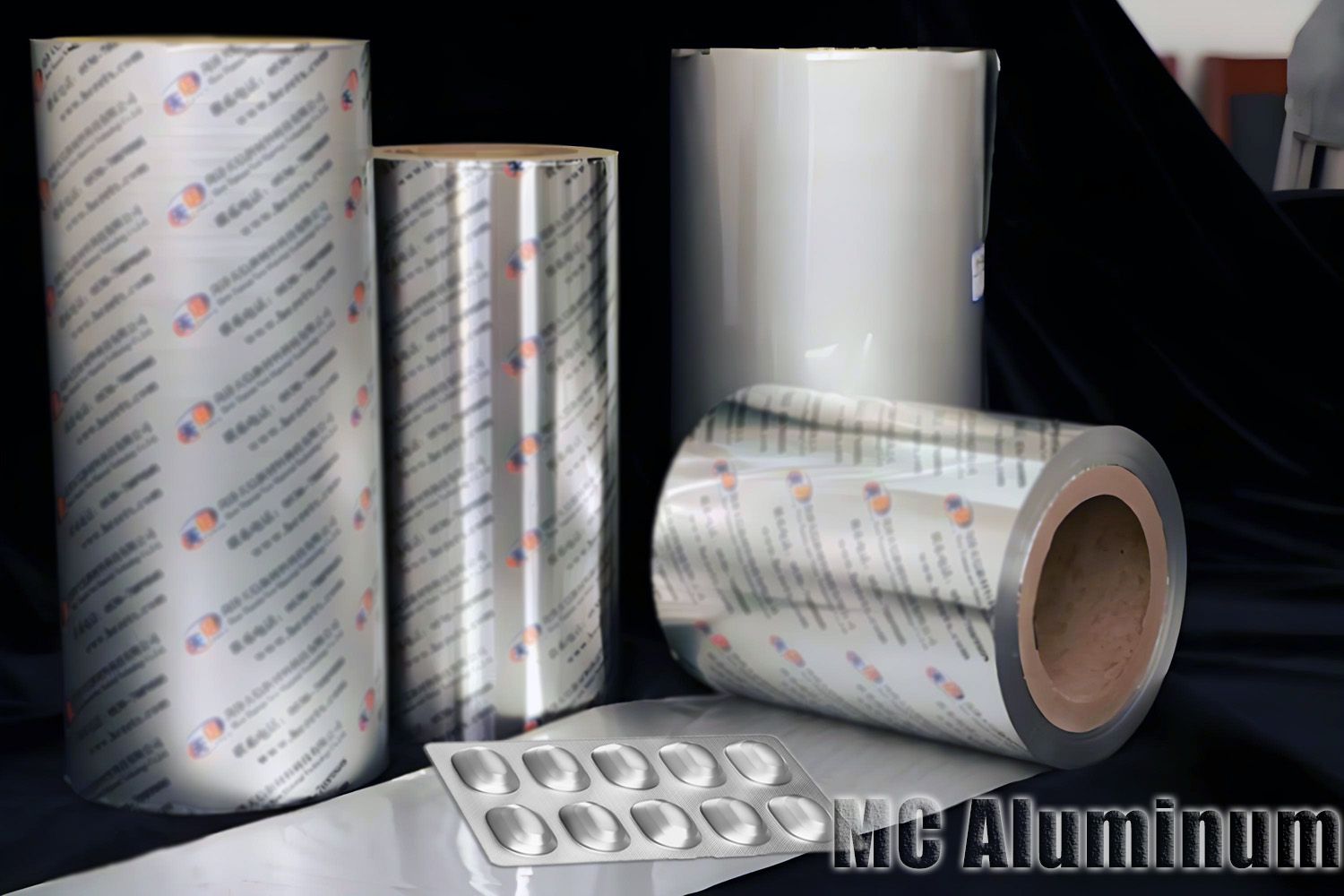

Printed aluminum foil for PTP

The PTP aluminum foil produced by MC Aluminum includes plain foil (no printing), printed foil (single-sided printing, double-sided printing, monochrome printing, two-color printing, multi-color printing), color foil (single-sided gold, double-sided gold, green background, various color backgrounds), anti-counterfeiting (invisible writing, pattern, front and back printing), etc., which can be printed on one side or two sides according to requirements to ensure better appearance.

PTP Aluminum foil Advantage:

1. Excellent sealing strength with PVC, PVC/PVDC, PET, PP, PE and high barrier base webs

2. Primer system suitable for online and offline printing, easy to print with water-based and UV inks

3. Perfect printing, no fading after sealing

4. According to customer requirements: single-sided, double-sided printing

5. Low temperature sealing, suitable for pharmaceutical and high-speed processing

6. Strong barrier to moisture, oxygen, other gases, light and UV.

PTP Aluminum foil Specification:

| Structure | OP/printing ink/aluminum/(adhesive) VC |

| Alloy | 1100, 1200, 1235, 1145, 3003, 8006, 8011, 8011A, 8079 |

| Thickness | 0.024-0.030 mm |

| Width | 80-1000mm |

| Coiling diameter | 275-500mm |

| Core ID | 76 mm, paper core; |

| Main products | printed aluminum foil, non-printed foil |

| Application | Blister foil can be used for blister packaging of tablets, pills, capsules and other medicines as well as candies. |

Mechanical ability

Grades | Temper | Thickness(mm) | Tensile strength/Mpa | Elongation/% |

| 1235 | O | 0.018-0.025 | 40-100 | 1 |

>0.025~0.040 | 50-110 | 4 | ||

>0.040-0.100 | >0.040-0.100 | 8 | ||

1100, 1200, 1235 | H18 | 0.018-0.100 | ≥135 | - |

1100, 1200 | O | 0.018-0.025 | 40-100 | 1 |

>0.025-0.040 | 50-110 | 3 | ||

>0.040-0.100 | 55-110 | 6 | ||

| 3003 | O | 0.018-0.025 | 80-130 | 1 |

>0.025-0.040 | 80-130 | 4 | ||

>0.040-0.100 | 80-130 | 8 | ||

| 8006 | O | 0.018-0.025 | 80-140 | 1 |

>0.025-0.040 | 80-140 | 2 | ||

>0.040-0.100 | 80-145 | 6 | ||

H18 | 0.018-0.100 | ≥180 | 1 | |

8011, 8011A, 8079 | O | 0.018-0.025 | 55-105 | 1 |

>0.025-0.040 | 60-110 | 4 | ||

>0.040-0.100 | 60-110 | 8 | ||

H18 | 0.018-0.100 | ≥150 | 1 |

Application of PTP Aluminum foil:

Aluminum-plastic blister packaging for pharmaceutical tablets, capsules, pills, etc.

Packing & Delivery:

Each roll of goods is packed in PE bags, with gaskets and plugs at both ends, and then packed in cartons outside. Finally, the export products are packed in fumigation-free wooden pallets.

Contact Us

Address

- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com alummc@hotmail.com