- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com

ALU-ALU

Alloy:8011,8021

Thickness:0.14-0.16mm

Width:<700mm

Structure:OPA/AL/PVC

What is ALU-ALU foil?

ALU-ALU foil, also known as cold-formed blister foil, is a packaging material commonly used in the pharmaceutical industry to provide high protection for pharmaceutical products, especially those that are sensitive to moisture. This packaging consists of two layers of aluminum foil with a layer of polyvinyl chloride (PVC) or polyvinylidene chloride (PVDC) in between.

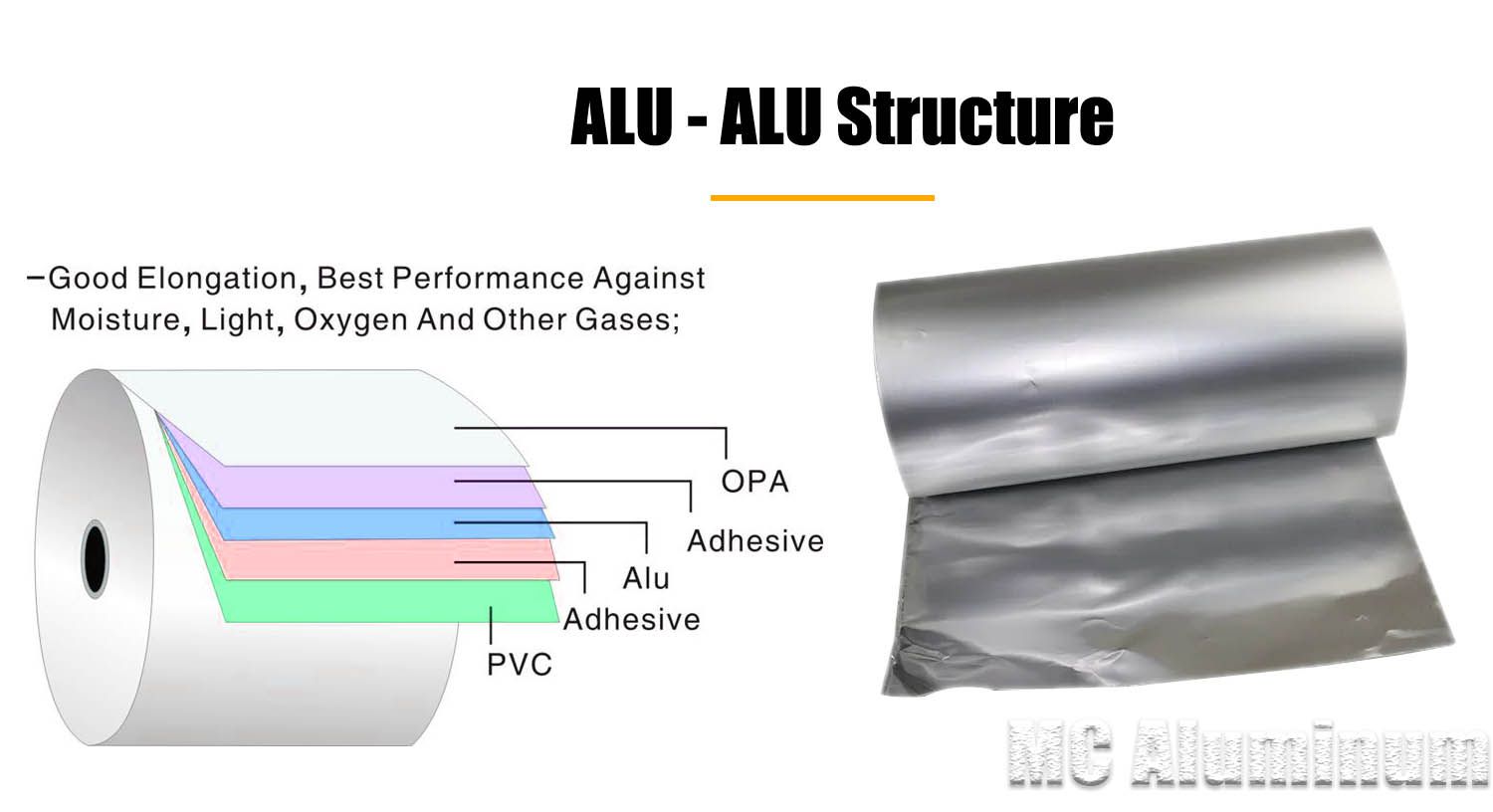

Composition and structure

ALU-ALU foil is usually configured with a three-layer structure of OPA (oriented polypropylene)/adhesive/ALU (8011 aluminum foil)/adhesive/PVC (polyvinyl chloride). This structure gives ALU-ALU foil excellent barrier properties, moisture resistance, anti-oxidation properties, and good printing adaptability.

OPA film: 25 microns

Adhesive: 4 g/m²

Aluminum soft foil: 45-60 microns

Adhesive: 4 g/m²

PVC film: 60 microns

Other specifications of aluminum foil configurations can be provided to meet customer requirements.

How is ALU ALU Foil formed?

The forming process for ALU ALU Foil involves cold forming, whereby the foil is formed into a cavity by applying high pressure. This process does not involve heating, making it suitable for use with sensitive products.

The foil passes through a forming unit where a Teflon-coated punch presses the foil into the cavity of the lower plate, forming the pocket required to hold the product.

ALU-ALU Advantage:

1. High barrier property: effectively isolates moisture, light and oxygen to maintain product stability and shelf life.

2. Durability: The double-layer aluminum structure is strong and puncture-resistant, protecting the drug from damage.

3. Thermoformability: It can be cold-formed, suitable for single-dose blisters that fix sensitive drugs.

4. Chemical resistance: Tolerant to most chemicals, ensuring drug stability.

5. Moisture resistance: Excellent moisture resistance, keeping the drug dry and preventing deterioration.

6. Tamper-proof seal: Provides a secure seal and easy to identify tampering.

7. Customizable design: A variety of capping options can be customized to meet different packaging needs.

8. Environmental protection: Some products are recyclable and meet environmental protection requirements.

ALU-ALU Specification:

| Alloy | 8011,8021,etc |

| Temper | O |

| Thickness | 140 - 160 microns |

| Width | <700 mm |

| Winding diameter | 240 mm - 280 mm, tolerance +/- 5 mm |

| Core diameter | 76 mm, tolerance +/-0.5 mm |

| Main material | aluminum / steel / cardboard |

| Structure | OPA / AL / PVC |

| Printing | customizable |

| Usage | pharmaceutical blister packaging |

Application of ALU-ALU:

Pharmaceutical packaging: ALU-ALU foil is widely used in blister packaging of tablets, capsules and other drugs, providing an independent sealed protective environment for each drug, preventing the drug from getting damp and deteriorating, and extending the shelf life of the drug.

Medical devices: Used to package some small medical devices or reagents to prevent them from being affected by air, light and moisture.

Health products and food supplements: For some health products that are sensitive to humidity and light, such as vitamin and mineral capsules, ALU-ALU foil is also often used for packaging to ensure product stability and effectiveness.

Chemical products: Some small-dose chemical reagents and fine chemical products that need to be individually packaged are also packaged in ALU-ALU foil to prevent product deterioration or chemical reactions.

Packing & Delivery:

Contact Us

Address

- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com alummc@hotmail.com