Aluminum fins are the core component of heat exchangers in air conditioning systems, and their performance directly affects the cooling or heating efficiency and the overall energy performance of the system. These thin and flat metal sheets are typically arranged in neat rows and mounted onto copper or aluminum tubes, which greatly increases the surface area of the heat exchanger. This structure allows for more efficient heat exchange between the air and the refrigerant.

When the air conditioner operates, indoor air flows across the surface of the fins and exchanges heat with the refrigerant flowing inside the tubes-achieving either cooling or heating of the air.

Aluminum has become the preferred material for fins thanks to its excellent thermal conductivity, good corrosion resistance, easy formability, lighter weight, and lower cost compared to copper. Moreover, aluminum naturally forms a thin, dense oxide film on its surface, which, while not completely preventing corrosion, can significantly slow down further corrosion processes.

Common Aluminum Fin Material Models

In the air conditioning manufacturing industry, the most commonly used and mature aluminum fin materials are mainly concentrated in the 1000 series, 3000 series, and 8000 series alloys:

1100 aluminum foil

3003 aluminum foil

3102 aluminum foil

8011 aluminum foil

Comparison of Aluminum Fin Material Characteristics

1100 Aluminum Foil

1100 aluminum foil is a pure aluminum material similar to 1060 aluminum, featuring good formability and corrosion resistance. It is more cost-effective and has slightly higher strength than 1060 aluminum. It is widely used in the production of fins for low- and medium-pressure heat exchangers.

3003 Aluminum Foil

3003 aluminum foil is an aluminum-manganese alloy with excellent corrosion resistance, good formability, and weldability. Its lightweight nature and excellent thermal conductivity make it a popular choice for forming aluminum fins for air conditioners.

3102 Aluminum Foil

3102 aluminum foil is an aluminum-manganese-silicon alloy with good oxidation resistance, outstanding corrosion resistance, and excellent formability. It resists deformation during fin forming, making it suitable for high-pressure heat exchangers.

8011 Aluminum Foil

8011 aluminum foil is an aluminum-iron-silicon alloy and a non-heat-treatable alloy. It has high plasticity and ductility, making it ideal for rolling into extremely thin foil to meet modern air conditioners’ demands for ultra-thin and high-density fins. Although its strength and corrosion resistance are slightly inferior to 3003, it performs well in fin applications. 8011 foil is commonly used in household air conditioners, small heat exchangers, and applications with strict thickness requirements.

Specifications of Aluminum Fin Stock

| Alloys | 1100, 3003, 3102, 8011 |

| Temper | O, H14, H22, H24, H26 |

| Thickness | 0.08 mm - 0.2 mm |

| Width | 100 mm - 1600 mm |

| Length | 100 mm - 6000 mm |

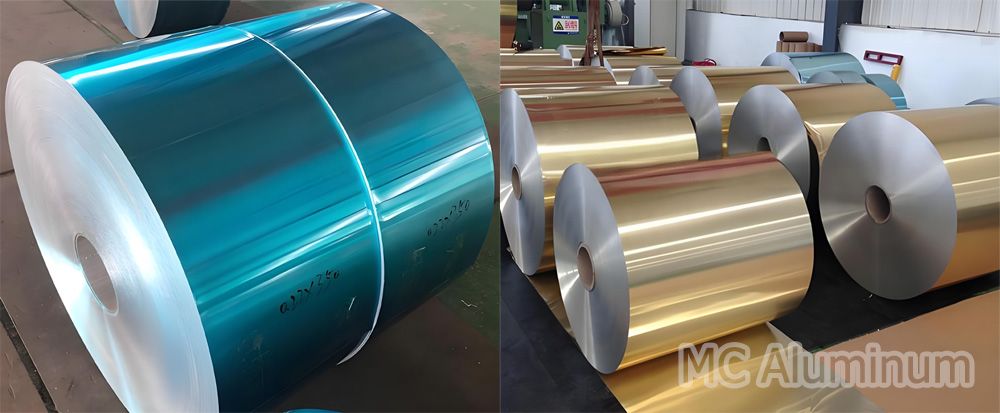

| Surface | Hydrophilic / Anti-corrosion / Galvanized / Mill finish |

Surface Treatment Technologies for Aluminum Fins

To enhance the performance and lifespan of aluminum fins, modern air conditioners often use various surface treatments.

Hydrophilic coating is the most common. It imparts excellent hydrophilicity to the fin surface, allowing condensate to spread evenly and drain quickly, reducing wind resistance and noise while improving heat exchange efficiency.

Anti-corrosion coating significantly enhances the durability of aluminum fins in humid and corrosive environments, extending the lifespan of the air conditioner. Furthermore, antimicrobial coating technology has also gained widespread application in recent years, particularly in hospitals, schools, and other places with high air quality requirements.

Quality and Testing Standards

High-quality aluminum fin foil must meet the following requirements:

Thickness, tensile strength, and elongation should comply with GB/T 3198 and other national or industry standards.

The surface should be clean, smooth, and free from oil spots, wrinkles, scratches, or corrosion marks.

The hydrophilic coating should have strong adhesion, resistant to peeling, heat, and humidity.

Anti-corrosion coating should withstand ≥ 500h salt spray testing (depending on product grade).

Coils should have good flatness to ensure smooth and efficient high-speed stamping during fin production.