Medicinal plastic packaging has been widely used in pharmaceutical packaging in recent years due to its light texture, high mechanical properties, corrosion resistance, convenient sealing, and low cost. Commonly used materials include PVC (polyvinyl chloride) materials, PVDC (polyvinylidene chloride) materials, PET/PE (polyethylene terephthalate/polyethylene) composite sheets and other types.

Common materials and characteristics

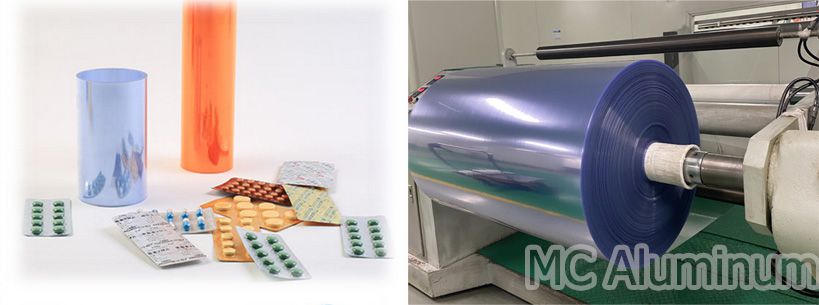

PVC hard sheet: good transparency, strong barrier properties, suitable for making pharmaceutical blister packaging (such as capsules, tablets).

PVDC hard sheet: excellent barrier properties, strong moisture and oxidation resistance. Mostly used for drugs with high barrier requirements, such as packaging of tablets and granules that are susceptible to moisture.

PE: good flexibility, low temperature resistance, and high chemical stability. Suitable for making soft packaging such as infusion bags and eye drop bottles.

PET: has the advantages of excellent transparency, high strength, and good moisture resistance. Used to make pharmaceutical bottles (such as vitamin bottles).

Medicinal plastic packaging has many characteristics and advantages:

Safety: Medicinal plastic packaging materials comply with relevant standards and regulations, are non-toxic, harmless, and odorless, and can ensure the safety and effectiveness of drugs.

Lightweight: The density of plastic is low, which reduces the weight of packaging materials and is convenient for transportation and carrying.

High mechanical properties: It has good tensile and impact resistance, and can effectively protect drugs from physical damage.

Corrosion resistance: It has good resistance to chemicals such as acids, alkalis, and salts, and is suitable for the packaging of a variety of drugs.

Easy to seal: It is convenient to compound with materials such as aluminum foil to ensure the sealing and moisture resistance of drugs.

Cost-effectiveness: Compared with traditional packaging such as glass or metal, plastic packaging has more cost advantages.

Application:

Solid medicine bottle: used to package solid drugs such as tablets and capsules. The material is usually PP or PET/PE, with good sealing and barrier properties.

Oral liquid bottle: PET/PE or PP is usually used to package oral liquid preparations, such as syrups, with good temperature resistance and chemical stability.

Ampoules: Designed for drugs that are protected from light and stored aseptically, such as injections, usually made of glass or special plastics to ensure the purity and sterility of the drugs.

Blister packaging: used for packaging solid drugs, with moisture-proof, dust-proof and pollution-proof functions, effectively protecting the quality and safety of drugs.