- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com

3003 Aluminum Foil

Alloy:3003

Thickness:0.06~0.2mm

Width:100~1500mm

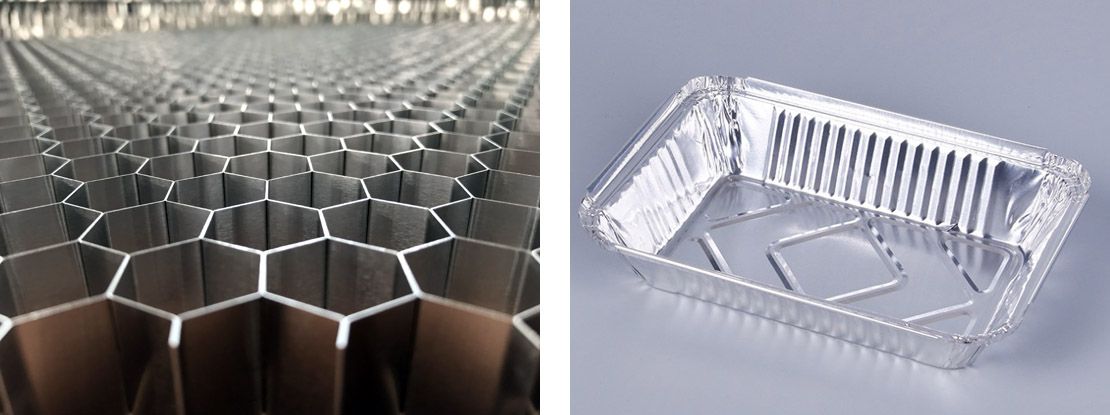

Application:Electronic foils, honeycomb materials, building sound insulation materials, food packaging, etc.

3003 aluminum foil belongs to Al-Mn series alloy. Due to the manganese element, 3003 aluminum foil has very good corrosion resistance and weldability, and has good formability. It is not heat treatable and develops strengthening from cold working only. Main tempers for aluminum foil 3003 includes H 18, H22, H24 and other tempers upon request. This alloy provides a better heating and cooling environment so that widely used in household applications.

3003 Aluminum Foil Advantage:

1. 3003 aluminum foil cannot be strengthened by heat treatment, with good corrosion resistance and good welding performance

2. High tensile strength.

3. Non-toxic, tasteless, safe and hygienic

4. Aluminum is a recyclable metal

5. Has excellent moisture-proof performance, shading and extremely high blocking ability

3003 Aluminum Foil Specification:

| Alloy | 3003 |

| Temper | H,O,H18,H14,H24,H26,H16 |

| Thickness | 0.06~0.2mm |

| Width | 100~1500mm |

| Coil ID | 76mm,152mm,408mm,508mm |

Application of 3003 Aluminum Foil:

Electronic foils, honeycomb materials, building sound insulation materials (via viaducts, high-speed railway sound insulation, etc.), food packaging, etc.

Packing & Delivery:

PE foam is the first layer, plastic bag is the second layer, and then montmorillonite desiccant is put in to prevent corrosion. Wrapped in paper as a third layer, the roll is suspended in a nautical-friendly wooden box, and the edges of the roll are protected from mechanical damage with Styrofoam.

Contact Us

Address

- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com alummc@hotmail.com