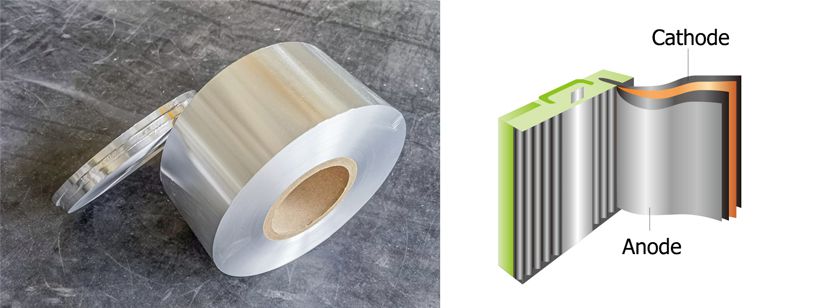

Aluminum foil is one of the cathode materials for lithium-ion batteries. The coating on its surface can improve the conductivity, chemical stability and mechanical strength of the cathode material, thereby improving the energy density and cycle life of the entire lithium-ion battery.

1235 battery-grade aluminum foil has good conductivity, stability, strong corrosion resistance and is easy to process and form, so it is often used in the preparation of lithium-ion battery electrodes.

The battery cathode foil production methods mainly include hot rolling, remelting aluminum ingot casting and rolling, and electrolytic aluminum liquid direct casting and rolling.

Battery aluminum foil specifications:

| Alloy | 1235, 1145, 1060, 1070,etc |

| Temper | H18 |

| Thickness | 0.015-0.06mm |

| Width | 30-1600mm |

| Length | 10-16000mm |

| ID | 75/155mm |

Resistors of 1145 and 1235 alloy aluminum foil (width 10mm) with different thicknesses

| Calibrated thickness/mm | 0.0060 | 0.0070 | 0.0080 | 0.0090 | 0.010 | 0.11 | 0.16 |

| Maximum resistance/(Ω.m) | 0.55 | 0.51 | 0.43 | 0.36 | 0.32 | 0.28 | 0.25 |

Battery cathode aluminum foil is widely used in household appliances, computers, communications, industrial controls, electric vehicles, electric locomotives, and military and aerospace equipment.

MC Aluminum specializes in the production of battery aluminum foil, with stable quality and complete models. The edges of the products are neat, without burrs and staggered layers. Factory direct sales, price concessions, exported to many overseas countries and regions, please send email for detailed information.