A Cultural Legacy

Hookah (also known as Shisha) is not just a recreational tool—it’s a cultural symbol with roots dating back to 16th-century India and Persia. During the 18th and 19th centuries, as hookah spread across the Middle East and the Ottoman Empire, people began placing clay discs, stone plates, and eventually fine metal meshes above the tobacco to separate it from the burning charcoal.

By the mid-20th century, industrial aluminum foil had become more widely available. Among them, 8011-O aluminum alloy foil, known for its ductility and thermal stability, quickly found new applications in food and heat-related uses. Clever hookah enthusiasts adopted it as a new medium for heat management—and so, hookah foil became a standard component in the hookah experience.

As hookah culture expanded from the Middle East and North Africa to Europe, the U.S., and Asia, hookah foil evolved into a specialized, commercial product. Today, companies like MC Aluminum export it widely to markets such as the Middle East, Turkey, Germany, the U.S., and Russia.

What Is Hookah Foil?

Hookah foil is a specialized aluminum foil designed to cover the bowl of a hookah. It is typically thicker, stronger, and more heat-resistant than standard kitchen foil, and is engineered specifically to meet the needs of hookah smoking.

Charcoal is placed on top of the foil, which then evenly distributes heat to the shisha tobacco (also known as “molasses” or “mu‘assel”) below, allowing it to vaporize without burning.

Materials and specifications

Main material: food-grade aluminum foil (thickness 0.015-0.03mm), taking into account thermal conductivity, flexibility and cost. Some high-end products use copper foil or aluminum-copper composite foil to improve high temperature resistance.

Size: square (common 10*10cm) or round (diameter 10-13cm), matching the standard hookah pot size.

Thickness Guide: Features & Use Scenarios

| Thickness(mm) | Characteristics | Recommended Use |

| 0.015 | Lightweight, budget-friendly | Occasional home use |

| 0.02-0.025 | Balanced strength and flexibility | Regular home or lounge use |

| ≥0.03 | Heavy-duty, heat-resistant | Professional hookah lounges |

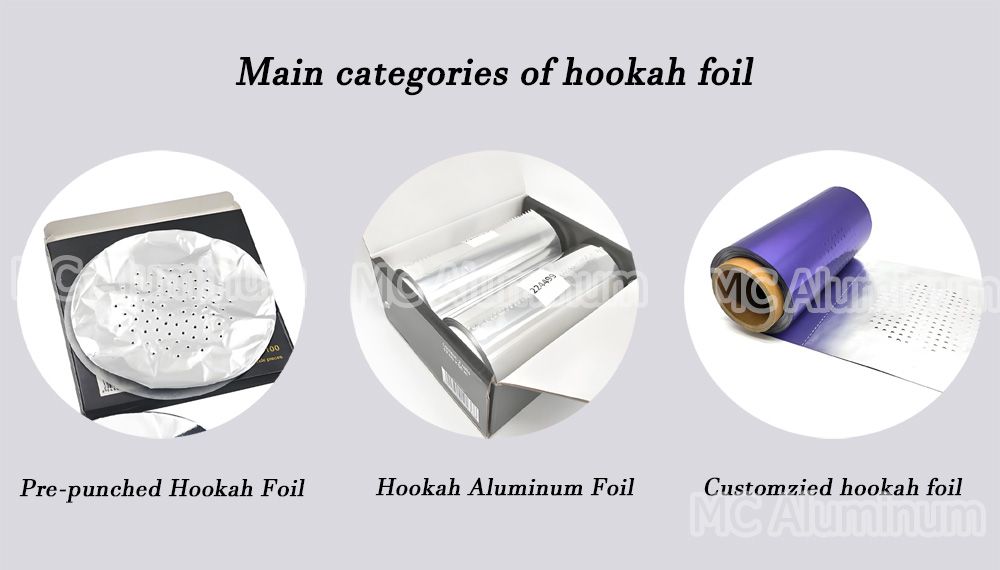

Types of Hookah Foil

Standard Hookah Aluminum Foil:

Thicker than kitchen foil, ideal for frequent users or hookah lounges. Requires manual perforation.Pre-Punched Hookah Foil:

Comes with uniform micro-holes (typically <1mm), eliminating the need to poke holes manually.Heavy-Duty Hookah Foil:

Thicker and more tear-resistant, it offers better heat management and longer durability. Ideal for long sessions or larger charcoal loads.

How to Use Hookah Aluminum Foil

Using hookah foil is simple:

Cover & Seal: Stretch the foil tightly across the hookah bowl. Ensure a snug fit around the edges for a complete seal.

Poke Holes: Use a poker or needle to create small holes in the foil surface. This allows airflow and promotes even heat distribution.

Place the Charcoal: Gently place pre-lit charcoal in the center. The heat will gradually warm the tobacco and produce rich vapor.

Why Is Hookah Foil Important?

1.Heat Control:

Foil acts as the primary barrier to regulate heat. Proper perforation and thickness help maintain ideal smoking temperatures, preventing overheating or burning.

2.Heat Distribution:

Ensures even heat flow across the entire bowl, allowing for consistent vapor production and better tobacco efficiency.

3.Ash Filtration:

Blocks ash or carbon residue from falling into the tobacco, delivering a cleaner and smoother smoking experience.

4.Protection:

Prevents direct contact between charcoal and tobacco, avoiding scorched flavors or burnt molasses.

Why Use 8011 Aluminum Alloy for Hookah Foil?

Excellent ductility: Easy to mold around hookah bowls

High-temperature resistance: Won’t melt or deform under heat

Food-safe: Non-toxic, odorless, and compliant with international safety standards

Puncture-resistant: Allows easy perforation without tearing, enhancing usability

Choosing the Right Foil for You

Are you a...

Consumer?

Choose 20μm or thicker food-grade hookah foil for a better experience and heat control.Retailer / Importer?

Opt for ISO or FDA-certified foil rolls or pre-cut sheets with customizable packaging to suit local market needs.OEM Buyer?

Focus on aluminum source (e.g., MC Aluminum’s 8011-O foil), annealing quality, punching accuracy, and packaging reliability to ensure consistency and scalability.