- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com

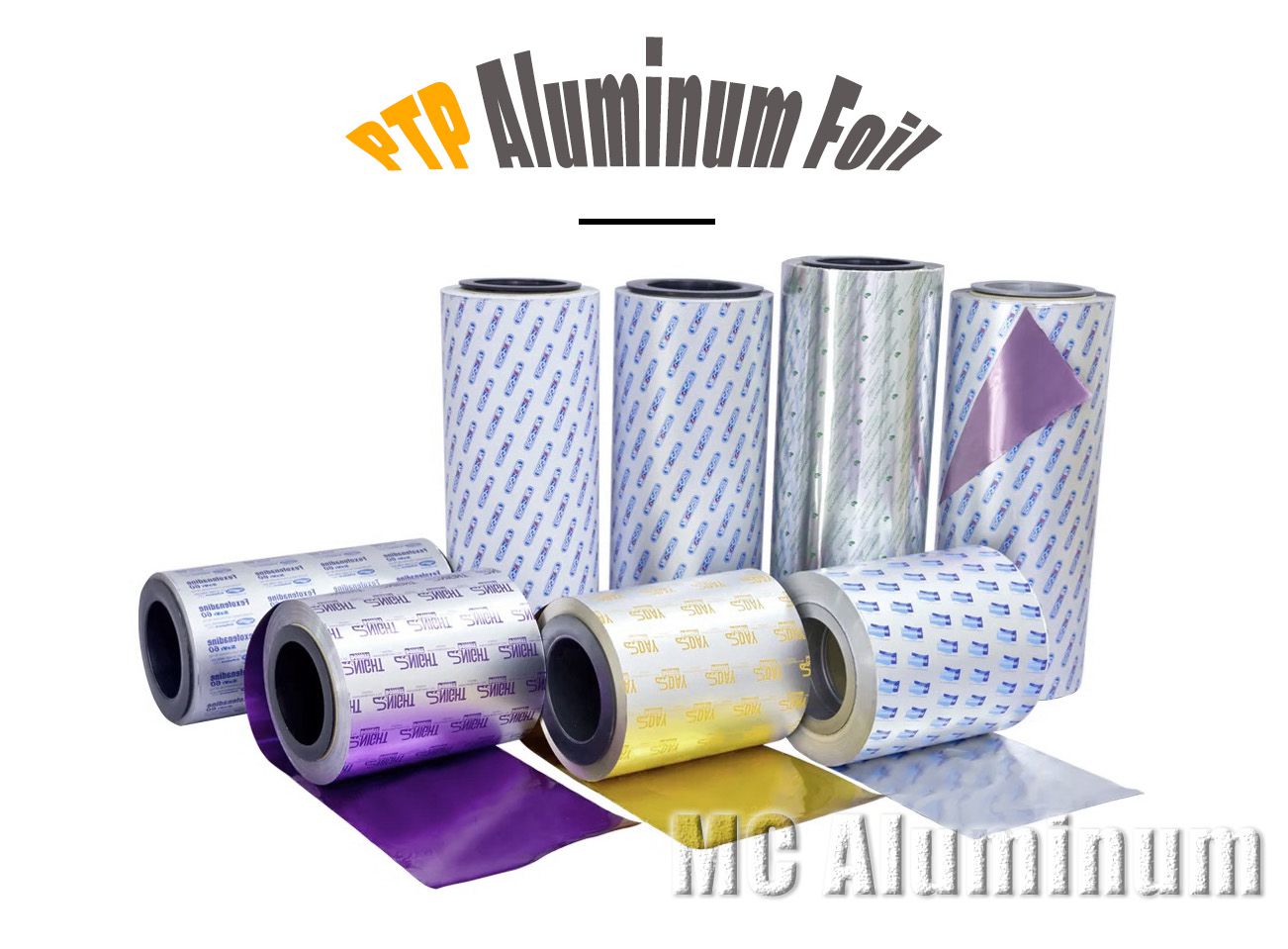

Aluminum foil for pharmaceutical packaging (PTP)

Alloy:8011, 8021, 8079

Thickness:0.025-0.028mm

Width:100-1600mm

Structure:OP/AL/VC

Aluminum foil for pharmaceutical packaging (PTP) Commonly known as: PTP aluminum foil, cold stamping aluminum foil, currently widely used in the production of aluminum-plastic blister packaging used for western medicine tablets and capsules. The entire medicine plate is called a pharmaceutical blister package. The transparent blister and the transparent plastic plate integrated with it are PVC hard sheets. The silver film attached to the hard sheet is the medicine foil, and the medicine foil is a downstream product produced by aluminum foil (MC aluminum product) after cutting, gluing, printing and other processes.

The surface of the PTP aluminum foil (AL) produced by MC Aluminum is printed, the outer layer is protected by varnish, and the inner layer is coated with heat-sealing glue (VC agent). The printed pattern is clear and colorful. It can be heat-sealed with PVC, PVC/PVDC, PP, NY/AL/PVC and other molding materials. It has good light-proof and barrier properties, and is easy to push or puncture, making it convenient to take medicine. Suitable for hard packaging of tablets, capsules, pills and other medicines.

PTP aluminum foil mostly uses 8011 aluminum foil, 8021 aluminum foil and 8079 aluminum foil, which are mostly in O state or H18 state, and the thickness is usually 25-28 microns. During the processing, the plate shape is required to be flat, brushed with A grade water, and free of oil stains, pinholes, bumps, scratches, oxidation, foreign matter and wrinkles. Its bright surface uses heat-sealed coating, and the matte surface uses printed processing coating. All coatings meet the characteristics of food safety and environmental protection.

Common pharmaceutical aluminum foil packaging material structure

| Product name | No printed aluminum foil | Single and double-sided printing foil | Single and double-sided colored foil |

| Typical structure | OP/AL/VC | OP/printing/AL/VC OP/AL/printing/VC OP/printing/AL/printing/VC | Color OP/printing/AL/VC OP/printing/AL/printing/color VC Color OP/printing /AL/printing/VC |

| Application | Tablets, capsules, effervescent tablets, pills, lozenges, special-shaped tablets, suppositories, ointments and other blister packaging. | ||

Aluminum foil for pharmaceutical packaging (PTP) Advantage:

1. Moisture-proof performance: It can effectively prevent drugs from getting damp, oxidized and deteriorating.

2. Barrier performance: It can effectively block light, oxygen, odor and microorganisms to protect the quality of drugs.

3. Heat sealing performance: Excellent heat sealing performance can prevent drug oxidation and contamination.

4. Processability: It can enhance performance through processes such as compounding and coating to meet different packaging needs.

5. Safety and hygiene: It is non-toxic, odorless, does not contain harmful substances, and meets drug hygiene standards.

6. Portability and convenience: Blister aluminum foil packaging is easy to separate and take out, suitable for personal use.

Aluminum foil for pharmaceutical packaging (PTP) Specification:

| Alloy | 8011, 8021, 8079 |

| Temper | O, H18 |

| Thickness | 0.025-0.028mm |

| Width | 10-1600mm |

| Length | C |

| Coating | Heat seal lacquer (HSL) and primer lacquer (OP) |

| HSL | sealed with pvc or pvc/pvdc or alu alu foil |

| ID | 76mm/152mm |

| OD | 240mm |

| Use | blister packaging of pharmaceutical capsules, tablets, etc. |

| Features | excellent gas barrier, moisture barrier, light barrier, drug resistance, chemical stability, hygienic, good heat sealability with PVC, PVDC, in the range of 130°C~200°C. |

| Packaging | Pe film/foam gasket/plastic plug/carton/pallet |

Application of Aluminum foil for pharmaceutical packaging (PTP):

1.Used for blister packaging of pharmaceutical capsules and tablets.

2. Used for bag packaging of powder particles and liquid medicines.

3. Used for bottled medicines, especially liquid medicines (such as antibiotics, infusions, etc.)

Quality requirements for medicinal aluminum foil:

Printing requirements:

High-precision printing, rich colors, and clear patterns. And it is required that the plain foil can be printed online on the automatic medicine blister packaging machine.

Moisture permeability and oxygen permeability requirements:

It is required to have good moisture permeability, moisture resistance, oxygen barrier, and seal with molding materials to avoid light and preserve fragrance.

Heat sealing and high humidity resistance requirements:

The protective layer has excellent high temperature resistance, and the adhesive layer after compounding must have good heat sealing performance. It can be heat-sealed with PVC, PVC/PVDC, NY/AL/PVC and other composite sheets, and the sealing must be good.

Ease of use requirements:

Aluminum foil is used as the base material, which is easy to open or puncture, making it convenient for consumers to take.

Convenience and anti-pollution requirements:

The blister board of aluminum foil medicine packaging is easy to carry, easy to transport and store, and prevent pollution.

Automatic packaging line production efficiency requirements:

The coiled product of aluminum foil medicine package is suitable for high-speed automated production in pharmaceutical factories.

Packing & Delivery:

Contact Us

Address

- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com alummc@hotmail.com