- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com

Cold Forming Aluminum Foil

Alloy:8021-O

Thickness:140-160 microns

Width:≤630mm

Structure:NY (OPA) / Al / PVC

Cold stamped aluminum, also known as cold-formed aluminum foil or cold-stamped aluminum, is a new type of pharmaceutical packaging material with high barrier properties and is also the best packaging material currently available. It can almost completely isolate water vapor, oxygen and ultraviolet rays. A single blister forms an independent part and has no effect on other drugs. It is mainly used for the packaging of sensitive drugs. Unlike traditional blister aluminum foil (PTP aluminum foil), cold stamped aluminum can be formed into a deep groove structure by cold pressing without heating, so as to adapt to different shapes of drugs. It is especially suitable for the packaging of moisture-sensitive, light-sensitive, and easily oxidized drugs.

Comparison between cold stamped aluminum and PTP aluminum foil

| Features | Cold stamped aluminum | PTP aluminum foil |

| Forming method | Cold stamping | Thermoforming |

| Barrier performance | Very high | High |

| Applicable drugs | Highly sensitive drugs | Conventional drugs |

| Molding depth | Maximum about 12mm | Usually shallower, about 8mm |

| Production cost | Higher | Lower |

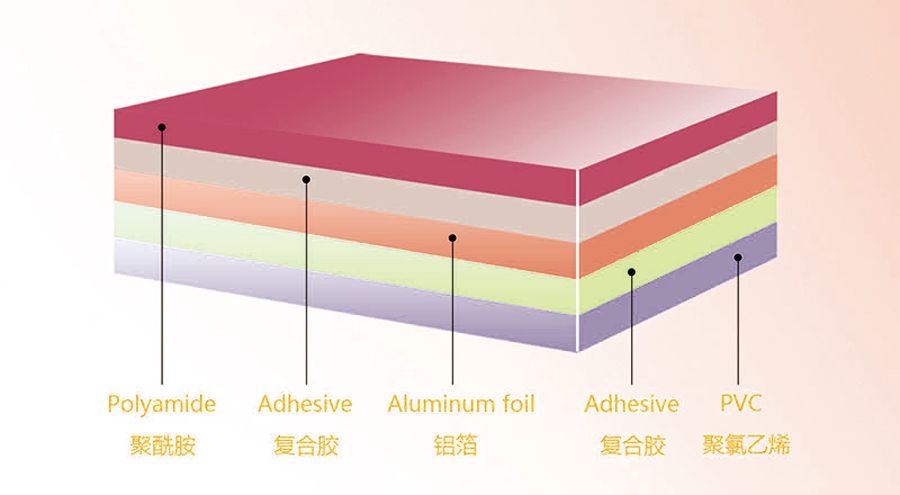

Structure of cold-formed aluminum foil:

Cold-formed aluminum foil is usually a multi-layer composite structure, which is composed of aluminum foil and other barrier materials to ensure that the packaging has excellent mechanical strength and barrier properties. The common structure is three layers:

OPA (nylon) layer + aluminum foil layer + PVC (or PP) layer

Nylon (OPA) layer: the outer layer material, which provides high tensile strength and impact resistance for cold-formed aluminum, making it not easy to break during the cold forming process, and also provides certain barrier properties.

Aluminum foil layer (Al): the middle layer, usually 45-60 micron thick pure aluminum foil, is the main barrier layer, with extremely high moisture resistance, oxygen resistance and light resistance, effectively protecting the stability of the drug.

Polyvinyl chloride (PVC) or polypropylene (PP) layer: the inner layer material, directly in contact with the drug, has good heat sealing and chemical resistance to ensure the safety of the drug and the sealing of the packaging.

| Width | Thickness (μm) | Roll inner diameter | Roll outer diameter | |||

| AL(AA8021) | PVC | |||||

≤900mm | 25 | 46-60 | 60 | 76mm | 220-400mm | Customizable |

| Ratio of cold stamped aluminum to PTP: 4:1 & 4.7:1 | ||||||

Aluminum foil base alloy for cold-formed pharmaceutical foil: 8021-O aluminum foil, 8079-O aluminum foil, thickness 0.025-0.08mm; with high cupping value, high heat sealing strength, no pinholes, good sealing, etc. We are the supplier of raw materials for cold-formed pharmaceutical aluminum foil for various foreign pharmaceutical packaging companies.

Processing requirements for cold-formed medicinal aluminum foil:

1. Flat plate shape;

2. Strict requirements on the plate surface, no black oil spots, scratches, small black silk, bright lines, roller-printed concave and convex points, mosquitoes, etc.;

3. No pinholes or holes, and pinholes must be eliminated if found;

4. Edge cutting quality, no burrs, towers, layer channeling, lotus leaf edges, flanges, and concave and convex lighting phenomena;

5. Water brushing must meet Class A standards;

6. Packaging should be moisture-proof to avoid oxidation.

Cold Forming Aluminum Foil Advantage:

1. High barrier property: It can completely block moisture, oxygen and light, and extend the shelf life of drugs.

2. Deep drawing capability: It can reach 12 mm deep forming at low temperature, which can meet the packaging needs of various drugs (tablets, capsules, powders, etc.).

3. Chemical resistance: The multi-layer structure has good chemical stability and is not easy to react with drugs, ensuring the quality and safety of drugs.

4. High strength: It uses composite materials such as OPA and aluminum foil, which has high mechanical strength to prevent damage during transportation and storage.

5. Block ultraviolet rays: The aluminum foil layer effectively blocks ultraviolet rays and prevents drug degradation.

6. Environmentally friendly and recyclable: Aluminum materials can be recycled and reused, which meets the requirements of sustainable development.

Cold Forming Aluminum Foil Specification:

| Structure | NY (OPA) / Al / PVC |

| Alloy | 8021-O |

| Width | ≤630mm |

| Thickness | 140-160 microns |

| Length | 280mm or as per customer requirements. |

| ID | 76mm / 152mm (3 inches / 6 inches) |

| OD | 280mm |

| Roll length | 360m (for 150 micron thickness) / 330m (for 160 micron thickness) |

| Weight | 241gsm (150 micron) / 281gsm (160 micron) |

| Material density | 1.67g/m3 |

| Brewing depth | X<13mm |

| Appearance | The appearance color is mainly silver or gold, and the machine is punched into blisters, which can be customized |

| Application | Pharmaceutical packaging is used for pills, tablets, powders, suppositories, capsules and outer covers, instead of PVC or PVC/PVDC blisters. |

Application of Cold Forming Aluminum Foil:

Cold stamping aluminum is usually used for high-end packaging of pharmaceutical blister packaging (such as capsules, tablets, etc.), and is also widely used in some drugs that are very sensitive to the external environment, such as:

(1)Antibiotics

(2)Hormone drugs

(3)Traditional Chinese medicine granules or powders

(4)Biological products and vaccines

Packing & Delivery:

Inner packaging: PE bag, plastic plug, foam gasket

Carton size 290*290*(width+10)mm

Outer packaging: carton, yellow tape (for packaging without pallet), pallet, film packaging

Contact Us

Address

- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com alummc@hotmail.com