Battery aluminum foil is a new type of composite aluminum foil material used as the current collector of lithium-ion batteries. Generally, the lithium battery industry uses rolled aluminum foil as the positive electrode current collector, which is used in ternary batteries, lithium iron phosphate batteries, and sodium-ion batteries. wait.

Rolled foil thickness varies from 10 to 50 microns. Commonly used pure aluminum foils for lithium batteries include various alloy grades such as 1060, 1050, 1145, and 1235, and are available in states such as -O, H14, -H24, -H22, and -H18.

Specification:

| Alloy | 1235,1145,1060,1170 |

| Temper | H18 |

| Tensile strength | ≥150N/mm |

| Elongation | ≥1% |

| Resistors of 1145 and 1235 alloy aluminum foil (width 10mm) with different thicknesses | |||||||

| Calibrated thickness/mm | 0.0060 | 0.0070 | 0.0080 | 0.0090 | 0.010 | 0.11 | 0.16 |

| Maximum resistance/(Ω.m) | 0.55 | 0.51 | 0.43 | 0.36 | 0.32 | 0.28 | 0.25 |

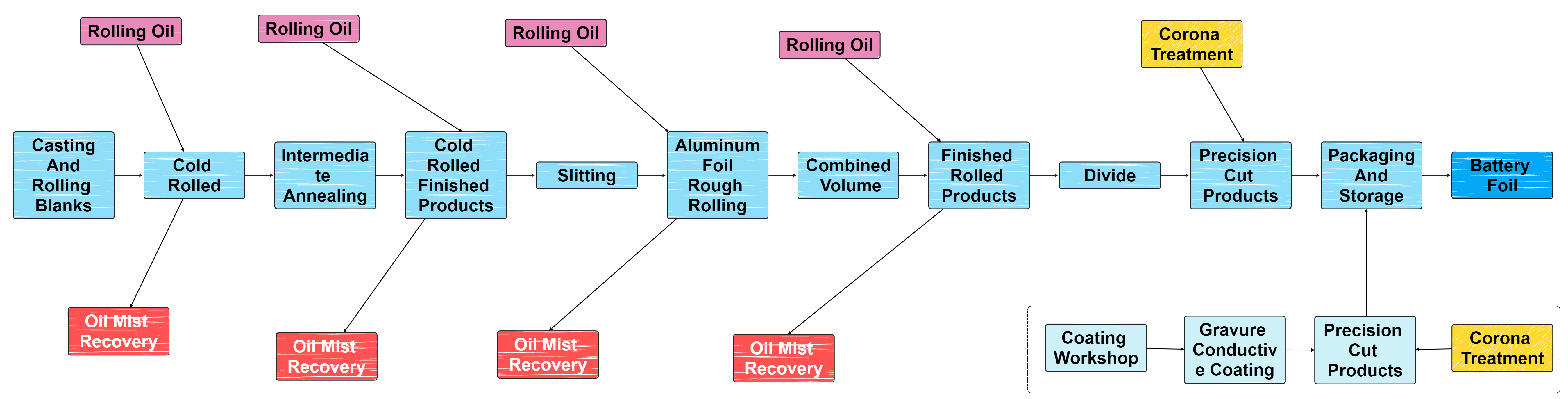

Lithium battery pure aluminum foil production process flow chart:

Battery aluminum foil performance characteristics:

1. Electrochemical properties: It has good electrical conductivity and is adaptable to different working environments and temperature conditions.

2. Mechanical properties: It has good ductility and processability, and is easy to stamp, stretch, etc. Stable mechanical performance, safe and reliable.

3. Corrosion resistance and oxidation resistance: A dense oxide film forms on the surface of the aluminum foil to prevent the intrusion of oxygen, moisture and other substances.

The quality and performance of the Lithium battery positive electrode aluminum foil directly affects key indicators such as the battery's energy density, charge and discharge rate, and cycle life. Therefore, the aluminum foil produced by MC Aluminum pursues the thinnest thickness, highest strength, highest dyne value, The six extreme values are the smallest thickness difference, the best plate shape, and the cleanest surface.