8011-H18 aluminum foil is a key material in the food and pharmaceutical packaging industries. With its high ductility, precise stamping properties, and excellent barrier performance, it has become the preferred base material for modern lightweight sealing solutions. It is widely used for sealing dry goods such as milk powder and coffee powder, as well as for the easy-pull lids on liquid products like yogurt and beverages. It has also expanded into pharmaceutical blister packaging (PTP aluminum foil), cosmetic bottle caps, and other applications that require stringent hygiene and safety standards.

8011 aluminum foil is made from aluminum as the base material, with small amounts of alloying elements (such as iron and silicon), offering both mechanical stability and tearability, making it suitable for high-speed automated production lines. The foil undergoes specific processing to achieve the H18 temper, which represents a degree of work hardening that gives the foil both strength and ductility, making it suitable for complex forming requirements.

Performance Advantages of 8011 Aluminum Foil Lids:

1. High Barrier Properties: Effectively protects the contents from external environmental factors, extending the product's shelf life. This makes it especially suitable for packaging food, pharmaceuticals, and other products with stringent packaging requirements.

2. Sealing Performance: Forms a strong bond when heat-sealed with plastic hard films, ensuring good sealing to prevent leakage or contamination.

3. Tearability: Soft yet with moderate yield strength, the foil can be precisely stamped and formed, making it ideal for easy-tear lids in automated production.

4. Barrier Properties: Excellent moisture and oxidation resistance, effectively protecting food and pharmaceutical products that are sensitive to humidity.

5. Hygiene and Safety: Complies with food-grade standards (GB/T 3880), non-toxic and odorless, suitable for direct contact with food and pharmaceuticals.

6. Environmental Friendliness: Aluminum foil is recyclable, supporting the trend of green packaging and reducing environmental impact.

Technical Parameters of Aluminum Seals:

| Material Grade | 8011-H18 Aluminum Foil |

| Thickness | 0.02mm - 0.2mm (customizable based on customer requirements) |

| Width | 100mm - 1200mm (customizable based on customer requirements) |

| Length | 100mm - 6000mm (customizable based on customer requirements) |

| Tensile Strength | 240 - 280 MPa |

| Yield Strength | 120 - 170 MPa |

| Elongation | 2% - 5% |

| Temper | H18 |

| Surface Quality | Smooth, without significant scratches or oil stains |

| Surface Treatment | Typically, surface brightening or coating treatment is applied to ensure corrosion resistance and maintain the appearance quality of the foil during use. |

Applications of 8011-H18 Aluminum Alloy Cap Material:

Easy-Open Lids (Pull-tab Lids):

8011-H18 aluminum foil is used to make easy-pull lids, offering excellent formability, easy opening, and good sealing properties. It is suitable for beverage cans, food cans, pharmaceutical cans, and more.Beverage and Food Can Lids:

8011-H18 aluminum foil’s corrosion resistance and oxidation resistance make it ideal for sealing canned foods, carbonated beverages, fruit juices, and other products.Pharmaceutical Packaging:

With its hygienic, safe, and reliable sealing properties, 8011-H18 aluminum foil is widely used in pharmaceutical packaging to protect medications from moisture and contamination.Other Sealing Applications:

In addition to easy-pull lids and can lids, 8011 aluminum foil can also be used in bottle caps, food packaging bags, and other packaging materials that require high strength and good sealing.

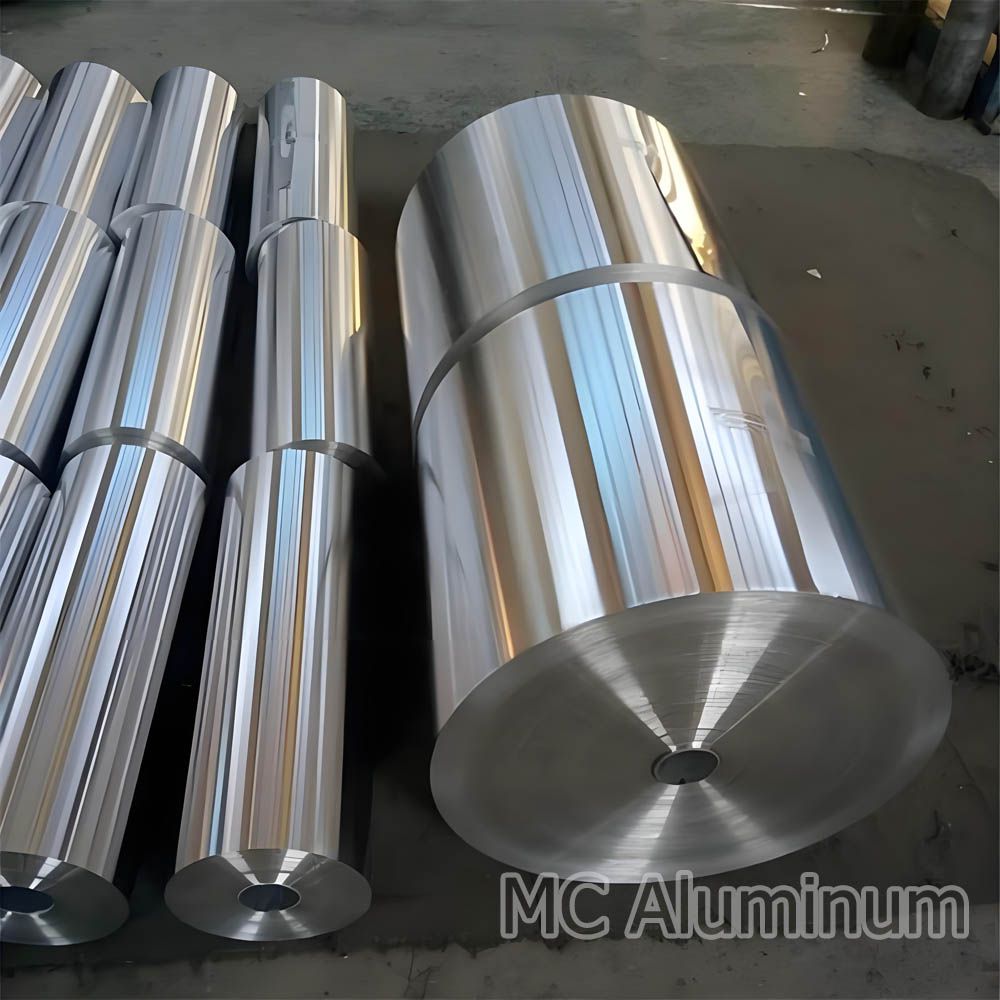

MC Aluminum Industry, as a professional aluminum foil manufacturer, specializes in producing aluminum foil for bottle caps. The 8011 easy-pull lid material offers stable physical properties, is easy to stamp, and has high strength. The surface is finely textured without black streaks or lines, and the tensile strength exceeds 165 MPa.