Among the materials selected for aseptic packaging, food packaging foil is the most common. 1235 aluminum foil is commonly used. This product is safe, hygienic and corrosion-resistant. It is a good choice as the basic material for aseptic packaging. 1235 aluminum foil has excellent characteristics. It is soft in texture and good in ductility, and its silvery white luster is bright and eye-catching.

The weight of aluminum foil in aluminum foil aseptic packaging only accounts for about 5% of the entire package. Its main function is to avoid light and block ventilation, keep the contents from being oxidized, reduce nutrient loss, and keep the taste fresh. 1235 aluminum foil has the characteristics of low energy consumption, less packaging materials, low manufacturing cost, high packaging efficiency, and high economic benefits. The quality is good and light, suitable for long-distance transportation, and waste packaging can be recycled and reused.

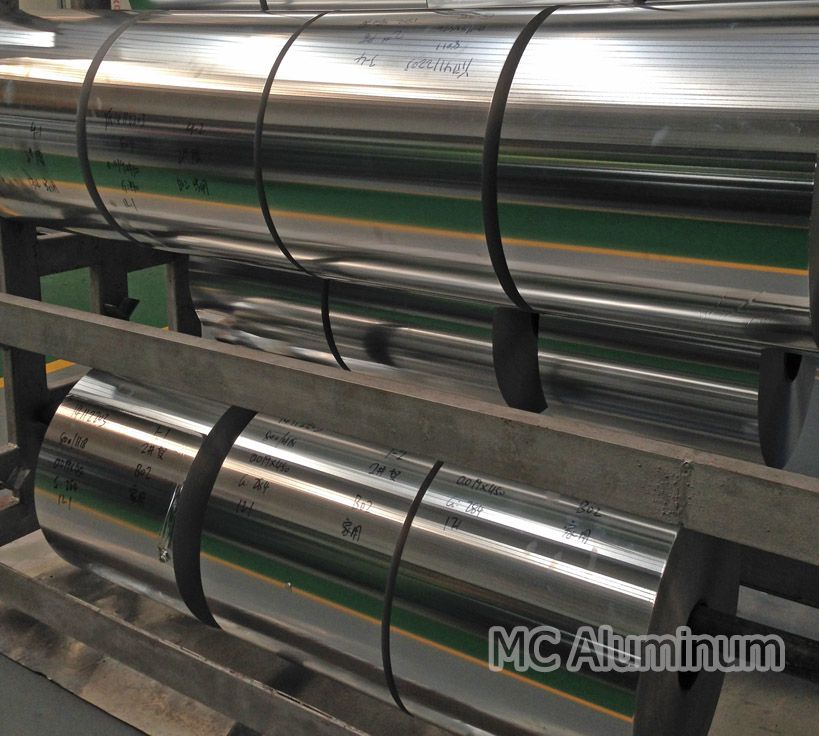

Aluminum foil aseptic packaging bags have the advantages of strong barrier, anti-oxidation, waterproof, moisture-proof, non-toxic and tasteless, high safety, high temperature resistance, low temperature resistance, and oil resistance. It is precisely because of so many advantages that aluminum foil packaging will become more and more popular. MC Aluminum has increased the research and development of aluminum foil production technology. The field of packaging is becoming more and more comprehensive, and products using aluminum foil packaging are becoming more and more popular.

MC Aluminum is a manufacturer specializing in the production of aluminum foil. The product specifications are complete and can be customized according to customer needs. The company has a huge production capacity and can accept orders of 1-200 tons. You are welcome to contact us by email at any time.