Air conditioning foil requires specific mechanical properties that support deep-drawing processes. High standards are set for yield strength, elongation, and Erichsen values, while surface quality demands not only flatness but also excellent wettability for hydrophilic coatings. For hydrophilic foil, surface wettability must reach Class A level.

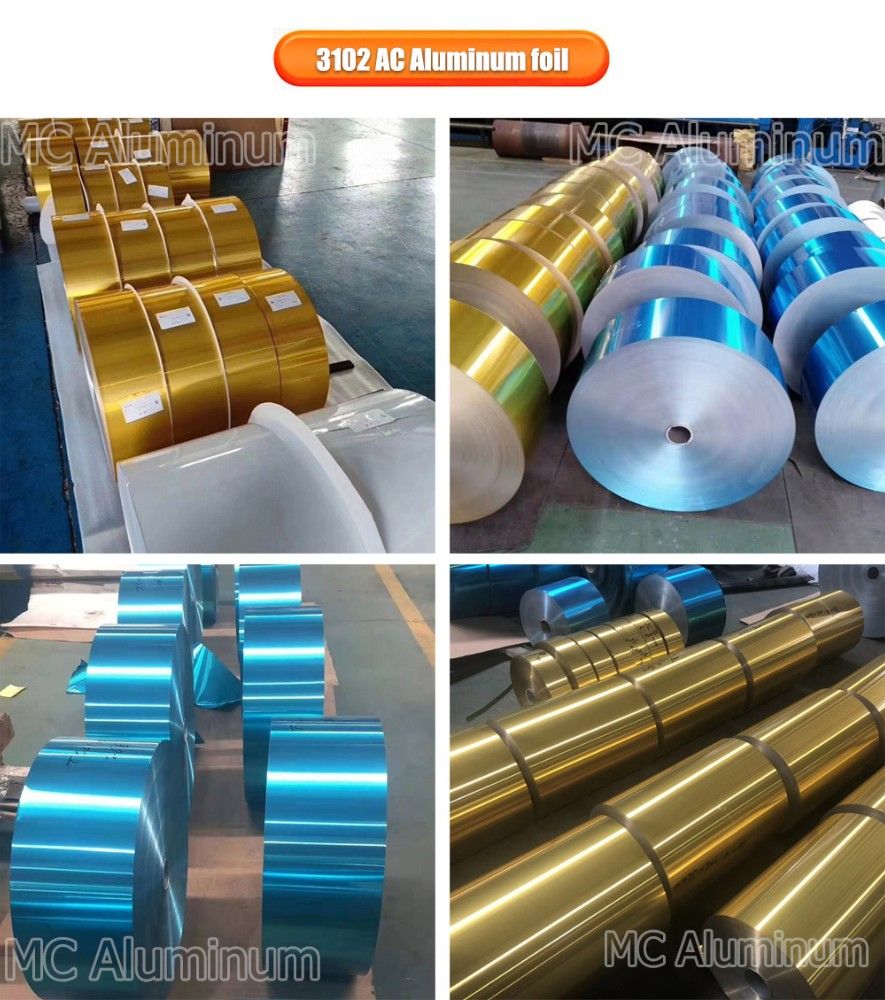

MC Aluminum supplies a wide range of air conditioner foils, including 8011, 1100, 3102, and 1120, with different alloy types tailored to diverse application needs.

3102 Aluminum Foil Overview

3102 aluminum alloy belongs to the Al-Mn anti-corrosion alloy series. Its mechanical properties can be enhanced via cold working tempers such as H22, H24, and H26, while the annealed state offers excellent elongation, making it suitable for complex stamping and forming.

Typical thickness ranges from 0.095 to 0.145 mm, and widths can be customized to meet the narrow width requirements of air conditioning heat exchanger fins.

Compared to standard alloys like 1050 or 8011, 3102 aluminum foil offers superior corrosion resistance, especially suitable for precision processing and coating applications in the refrigeration industry.

Coating Functionality

To meet the extreme conditions of air conditioning systems-high humidity, salt spray, and temperature fluctuations-3102 aluminum foil surfaces often receive the following coatings:

Hydrophilic Coating

Function: Reduces the water droplet contact angle to below 35°, allowing condensation to spread and flow off rapidly, preventing "water bridging" and improving heat exchange efficiency by 10-15%.

Application: Evaporator fins, improving cooling performance and energy savings.

Anti-Corrosion Coating

Function: Organic or inorganic coatings (e.g., epoxy resin) shield the aluminum from corrosive agents, extending service life by over 30%.

Application: Ideal for air conditioners in coastal or highly polluted environments to reduce corrosion powder and improve ventilation quality.

Hydrophobic Coating

Function: Increases the water contact angle to above 75°, accelerating water runoff-suitable for heating mode or dryers, preventing moisture retention.

Anti-Mold Coating

Function: Inhibits mold growth, avoids unpleasant odors, and enhances indoor air quality.

Application: Indoor heat exchanger fins for health-oriented air conditioning systems.

Product Specifications

| Alloys | 8011, 3102, 1100, 1120 |

| Tempers | H24, H26, O |

| Thickness | 0.095-0.145 mm |

| Width | 400-1600 mm (customizable) |

| Length | C |

| Colors | Blue, Gold, etc. |

| Coatings | Hydrophilic, epoxy resin, etc. |

| Surface Options | One-side coated / double-side coated / one-side bright & one-side coated |

| Thermal Conductivity | ≥ 160 W/m·K |

| Elongation | ≥ 15% (depending on temper) |

| Samples | Available |

| Packaging | Export-standard seaworthy wooden cases |

| MOQ | 1-3 tons |

Advantages of 3102 Air Conditioning Aluminum Foil

1. High Thermal Conductivity - Enhanced Heat Exchange

The 3102 alloy delivers excellent thermal conductivity. Coating layers do not compromise thermal performance, making it ideal for fins used in air conditioners, condensers, and radiators.

2. Superior Corrosion Resistance

With coated surfaces, the foil resists corrosion from chlorides, sulfides, acidic gases, and moisture, extending the service life-especially beneficial in coastal, humid, or polluted areas.

3. Hydrophilic Design - Anti-Condensation and Better Drainage

The hydrophilic coating allows condensation to spread quickly and drain efficiently, reducing airflow obstruction and noise, and improving air conditioning efficiency.

4. Excellent Stamping & Forming Performance

3102 foil features outstanding ductility and rolling properties, compatible with high-precision punching, stretching, and bending-ideal for automated fin punching machines.

5. Eco-Friendly and Non-Toxic - ROHS Compliant

All coatings use environmentally friendly resin systems, meeting international standards for home appliance manufacturing. Safe and reliable.

Typical Applications

Heat exchanger fins in indoor and outdoor air conditioning units

Central AC evaporators, condensers, and heat exchangers

Automotive air conditioning and cooling system fins

Fresh air systems, air source heat pumps, cold storage refrigeration units, and more

Packaging & Delivery

Inner Packaging: Moisture-proof plastic film + pearl cotton/paper core

Outer Packaging: Wooden crates or pallets suitable for ocean shipping