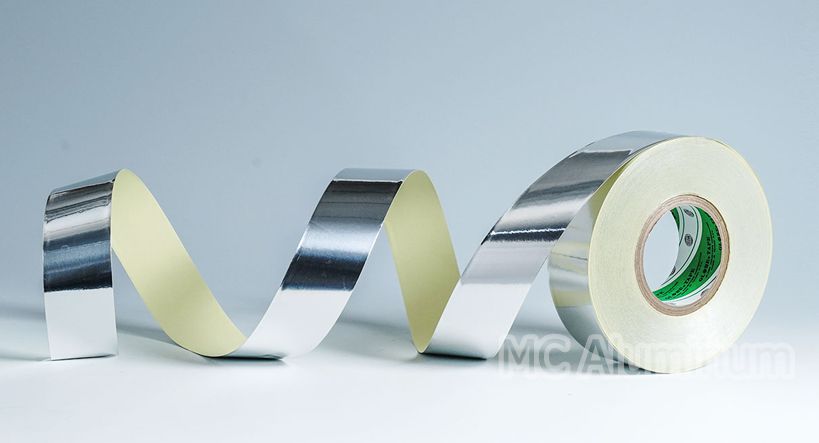

Aluminum foil tape is similar in appearance to the tapes we use daily, but its application range is different. It is mainly used in various electronic products such as PDAs, LCD monitors, notebook computers, copiers, and air conditioners that require electromagnetic shielding. The main components of aluminum foil tape are aluminum foil and pressure sensitive adhesive, the advantages are high temperature resistance, heat preservation and so on. The high temperature resistant aluminum foil tape can withstand a temperature of about 180°C to 200°C, which can basically meet the various needs of conventional industries in the market.

Tape aluminum foil can be used as 1235 aluminum foil and 8011 aluminum foil, which can be subdivided into soft state and hard state, mainly in O and H18 states; single-sided light and double-sided light, according to different performance requirements, the production process is also different. all the same.

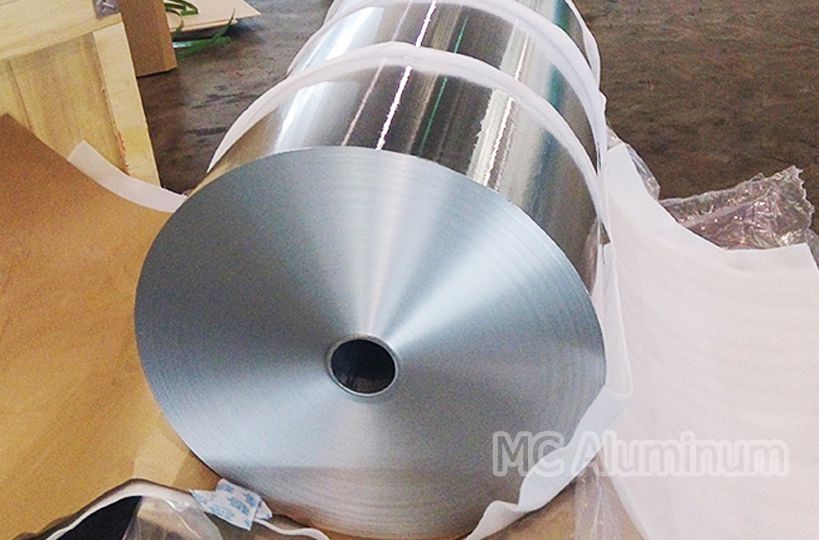

1235 aluminum foil: The aluminum content of 1235 aluminum foil is not less than 99.35%. Mingtai Aluminum can process 1235 aluminum foil with a thickness of 0.018-0.5mm. Used in cables, tapes, battery foils.

8011 aluminum foil: 8011 aluminum foil with a thickness of 0.016-0.5mm can be processed. This aluminum foil is mainly used in pharmaceutical packaging, food packaging, cable foil, milk cover material, sealing foil and other fields.

MC Aluminum is a professional aluminum foil manufacturer. The 1235 and 8011 tape foils produced by the company are clean in degreasing, less pinholes, good in shape, not deformed in cutting, and not easy to fall off after being glued. They are praised by foreign customers. The company has complete product specifications, fast delivery, and huge production capacity. It can undertake orders of 1-200 tons. After-sales is guaranteed, and customers can order with confidence!