The main raw material of solid pharmaceutical PVC rigid film is polyvinyl chloride (PVC) resin. This packaging material has a smooth and glossy surface, is transparent, and maintains uniform thickness. It features excellent formability, strong compatibility with PTP aluminum foil, and provides good barrier properties against oxygen and water vapor. After thermoforming, the blister is firm and resilient, offering reliable protection and support for the packaged content.

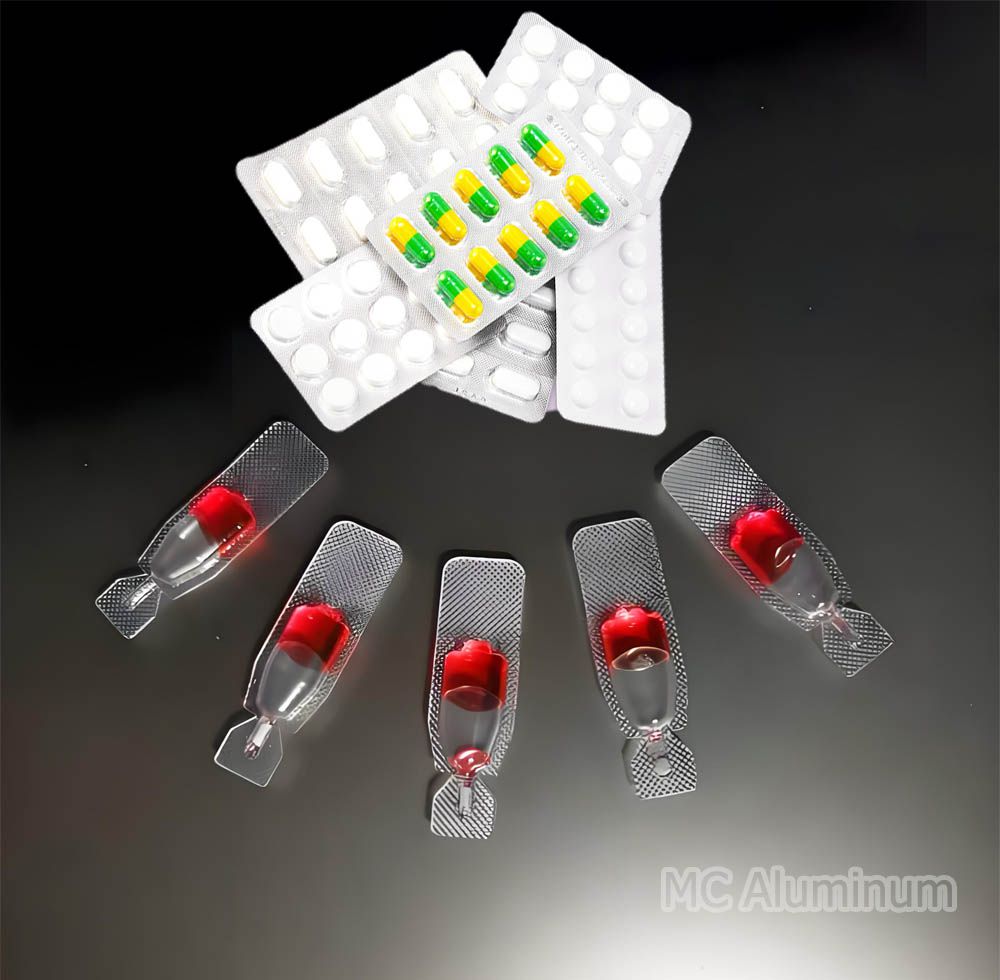

It is primarily used for solid pharmaceutical dosage forms, such as tablets and capsules, but is also suitable for injection trays, oral liquid trays, as well as food and health supplement packaging. PVC rigid film has stable physical properties, reacts poorly with only a few chemical solvents, and generally does not interact negatively with solid substances, ensuring the safety of pharmaceutical and food products.

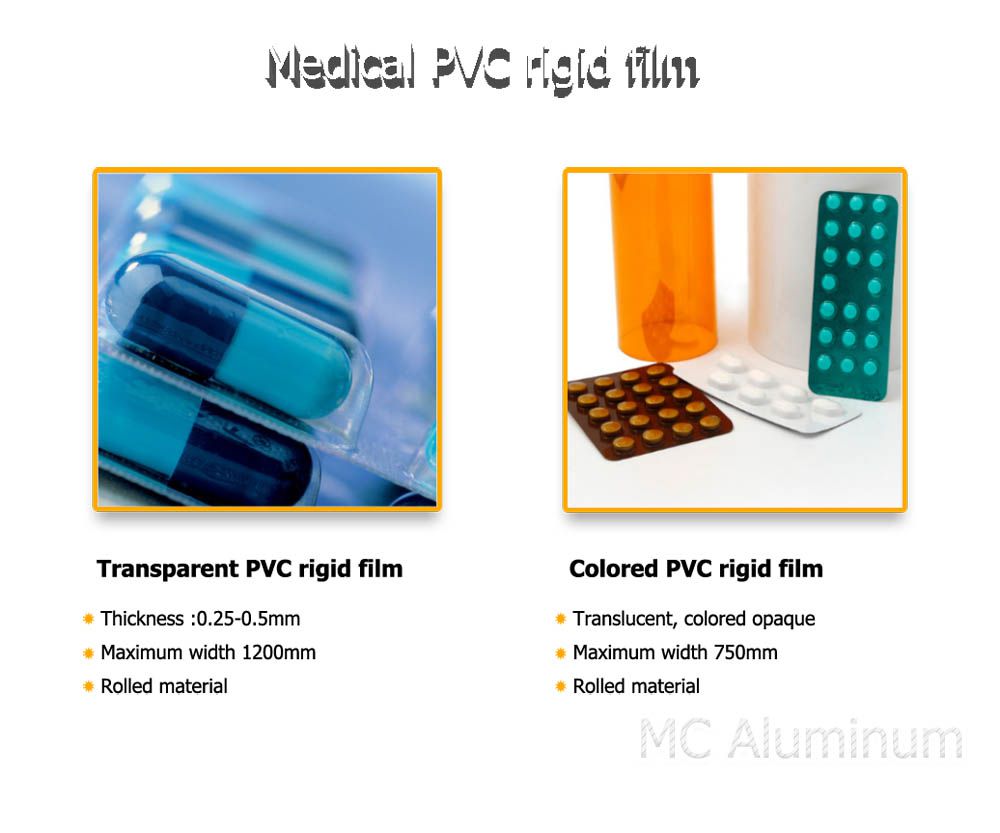

Specifications of Pharmaceutical PVC Film

| Thickness | 0.15mm – 0.80mm |

| Width | 60mm – 1300mm |

| Roll Diameter | ≤800 mm |

| Color | Customizable upon request |

| Product Features | Smooth and glossy surface, high transparency, uniform thickness, minimal crystal points and flow marks, few joints, excellent sealing properties, appropriate shrinkage rate, and tensile strength – all meeting the requirements of thermoforming and blister packaging. |

| Applications | Primarily used for blister packaging of solid drugs (e.g., tablets and capsules), and also for food, coating substrates, cosmetics, and electronics packaging. |

Key Features of PVC Rigid Film

1.High transparency:Allows clear visibility of the medicine’s appearance and color, enhancing user trust and product presentation.

2.Excellent barrier properties:Effectively blocks oxygen and moisture, prolonging shelf life of pharmaceuticals.

3.High mechanical strength:Superior stiffness and resistance to folding, minimizing breakage or deformation.

4.Good thermoformability:Wide range of forming temperatures, suitable for high-speed blister packaging machines.

5.Chemical stability:No significant interactions with most pharmaceuticals, ensuring product safety.

6.Cost-effective:Low material cost, mature production technology, and wide availability.

Application Fields

Pharmaceutical Packaging: Widely used in blister packs for tablets, capsules, injection trays, and oral liquid trays. Supports product form and protects against external contamination.

Food & Health Supplements: Suitable for packaging products with high barrier demands, such as moisture- and oxidation-sensitive nutritional supplements.