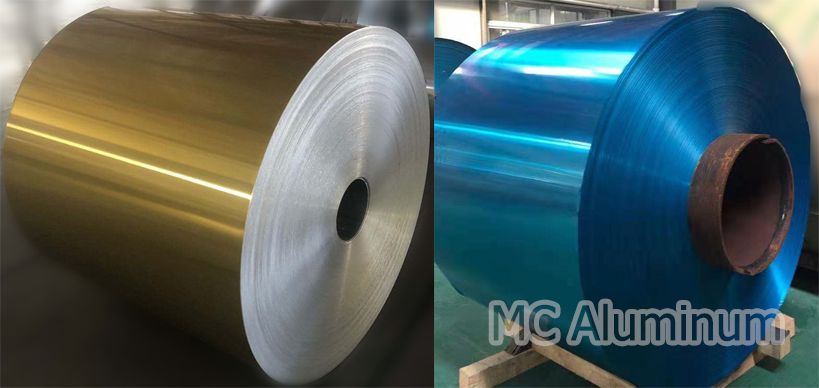

Hydrophilic coated aluminum foil is a composite material based on aluminum foil. It has good heat dissipation properties of ordinary aluminum foil, but also has corrosion resistance and hydrophilicity that ordinary aluminum foil does not have. It is an alternative to ordinary aluminum foil for air conditioning heat exchangers. product. MC Aluminum can provide blue hydrophilic aluminum foil and gold hydrophilic aluminum foil.

Hydrophilic aluminum foil is a hydrophilic treatment of aluminum foil. Through special processing, a hydrophilic layer is coated on the surface. The condensed water will spread quickly on the hydrophilic aluminum foil and will not condense into water droplets, thereby increasing heat exchange. area, speed up the cooling and heating speed, and effectively avoid the noise caused by condensed water blocking the air flow.

Hydrophilic aluminum foil usually uses alloy numbers: 1100, 1200, 8011, 1030, etc.

Hydrophilic aluminum foil specifications:

| Alloy | Temper | Thickness(mm) | tensile strength MPa | Elongatio n 50mm | Cupping value I.E.mm |

| 1100 | H22 | 0.09-0.20 | 95-135 | >15 | >5.5 |

| H24 | 0.09-0.20 | 125-145 | >13 | >5.0 | |

| 1200 | H26 | 0.09-0.20 | 125-160 | >10 | >4.5 |

| 8011 | H22 | 0.09-0.20 | 120-140 | >20 | >6.0 |

| H24 | 0.09-0.20 | 125-150 | >15 | >5.5 | |

| H26 | 0.09-0.20 | 130-155 | >10 | >5.0 | |

| 1030B | H26 | 0.09-0.20 | 130-155 | >9.5 | >4.5 |

Advantages of hydrophilic coated aluminum foil:

1. Excellent hydrophilicity, corrosion resistance, high temperature resistance, and mold resistance;

2. Good formability and no wear on the mold;

3. Improve heat exchange efficiency; the heat exchange rate can generally be increased by 10%-15%.

4. Easy to clean and maintain;

5. Widely used, suitable for food packaging, pharmaceutical packaging, cosmetic packaging, aluminum fins and other fields;

6. Reduce vibration and noise;

7. Environmental protection;