Aluminum foil fin heat exchanger is a new type of heat exchanger. It is a commonly used gas-liquid exchange equipment. Fin tube heat exchangers are widely used in many industries such as power, chemical industry, and air conditioning engineering. Aluminum foil fins Heat exchangers are mostly made of 8011 aluminum alloy, which has outstanding performance advantages and high cost performance, so it is very popular among users in the market.

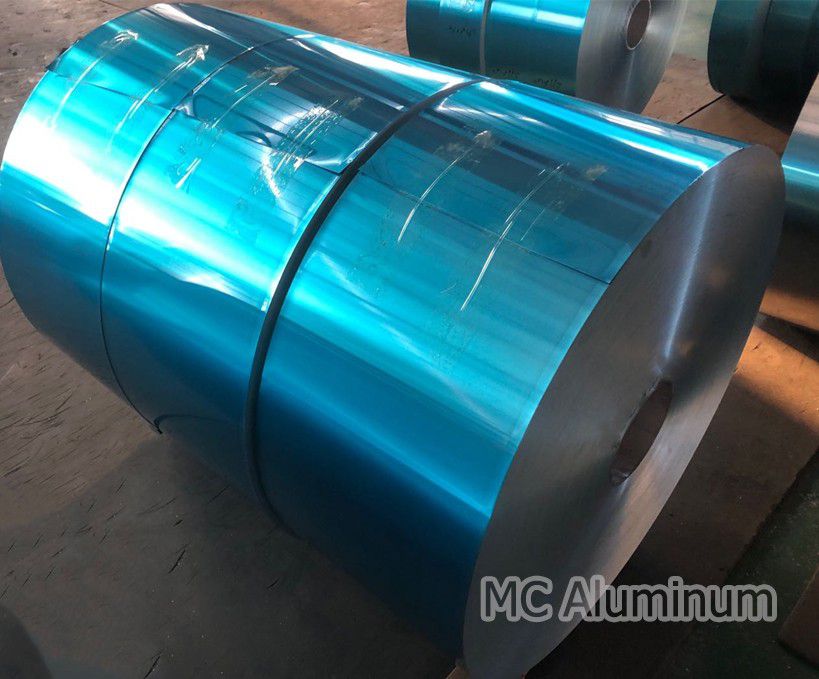

The manufacturing process of aluminum alloy fins usually involves rolling aluminum ingots into sheets or coils, followed by annealing and surface treatment to enhance formability and corrosion resistance. The surface of the fin blank can also be coated with corrosion-resistant material to further improve durability.

Aluminum fin blanks are typically made from high-grade aluminum alloys, such as 1xxx, 3xxx or 8xxx series alloys, which offer excellent thermal conductivity, corrosion resistance and formability. Process sheets or coils to obtain precise dimensions and surface properties suitable for fin processing.

Aluminum foil fins have the following characteristics:

1. Excellent heat dissipation performance: Aluminum foil fins have high thermal conductivity and excellent condensation performance, which can quickly transfer the heat of the heat dissipation carrier to the fins and quickly dissipate it into the air, reducing the temperature of the heat dissipation carrier.

2. Excellent environmental performance: Aluminum foil fins are usually made of environmentally friendly materials, which are non-toxic and harmless, do not contain fluoride, will not cause any pollution to the environment, and meet modern environmental protection requirements.

3. Strong corrosion resistance: The surface of the aluminum foil fins adopts special treatment technology to make it highly corrosion-resistant and less susceptible to corrosion damage after long-term use.

Aluminum fins are available in a variety of thicknesses, widths and alloy compositions to meet the specific requirements of different heat exchanger designs and applications. Its properties make it an ideal material for efficient heat transfer, helping to improve the performance and energy efficiency of various cooling and heating systems.