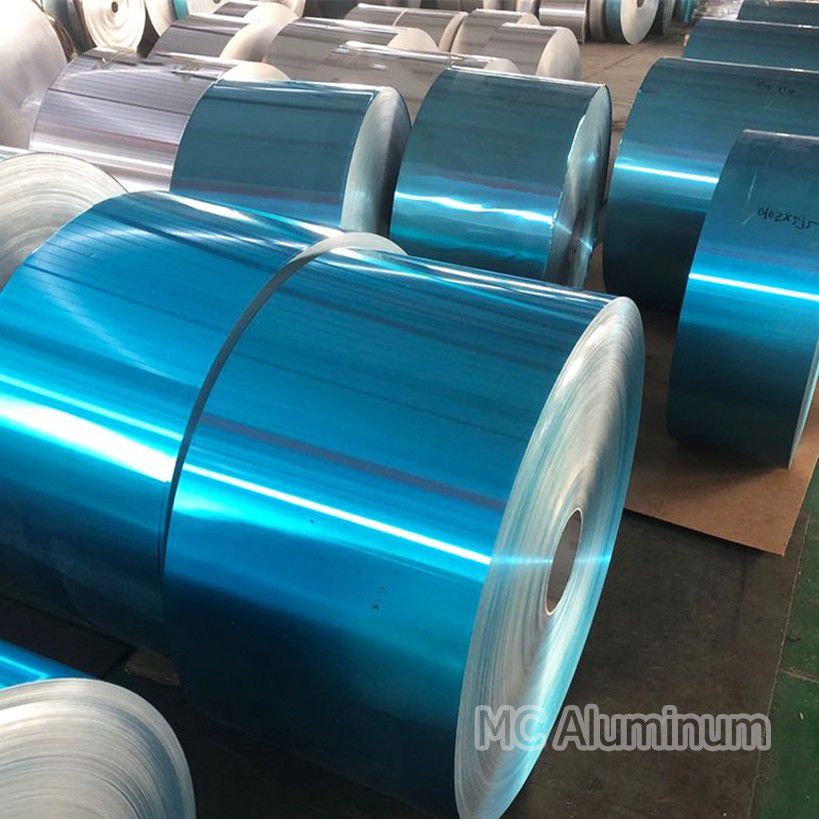

Hydrophilic aluminum foil fins are a new type of heat dissipation material that are widely used in refrigerators, air conditioners, computers, power supplies and other products. Blue hydrophilic aluminum foil is a commonly used material for hydrophilic aluminum fins. It has excellent heat dissipation performance and environmental protection performance. It can effectively reduce the temperature of the heat dissipation carrier and improve the stability and service life of the product. It can meet the needs of different industries and fields and has broad market prospects.

The hydrophilic film on the surface of the hydrophilic aluminum foil can effectively improve the hydrophilicity of the fins, evenly distribute the condensed water on the fins (eliminating water bridges between aluminum fins), and avoid condensate water "bridging" that will cause the unit's air volume to decrease and replace the Thermal efficiency is reduced.

Specifications of aluminum foil for hydrophilic coated fins:

| Alloy | 8011, 1100, 1060, 8006 |

| Temper | O, h14, h22, h24, h26 |

| Thickness | 0.03-0.5mm |

| Width | 50-1250mm |

| Length | C |

| ID | 75mm/150mm/300mm/400mm |

| OD | 400-1400mm |

| Coating thickness | 1.5~30μm |

| Initial contact angle | ≤10° |

| Continuous contact angle | ≤30° |

| Different levels of neutral salt spray | 500~3000 hours |

Advantages of hydrophilic coated fins:

1. Hydrophilic fins have fast cooling speed and strong cooling ability

2. It has good frost suppression ability and strong stability.

3. Hydrophilic fins have low power consumption and consume 5-8% more energy than ordinary fins.