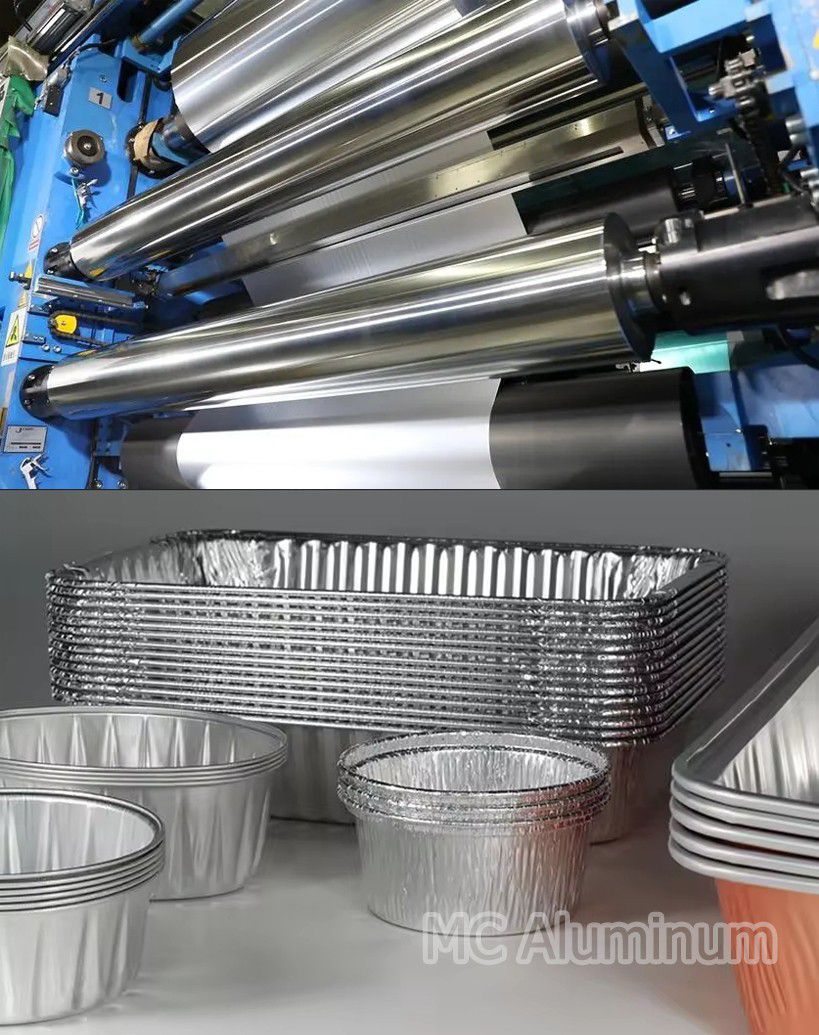

As a professional aluminum foil manufacturer, MC Aluminum specializes in the production of aluminum foil for food lunch boxes (it only provides polished aluminum foil substrates, without post-processing such as lamination and carbonization), focusing on the production of 3003 aluminum foil, 8011 aluminum foil, 8006 aluminum foil and other products. It has the advantages of clean surface, safe and hygienic product, and high elongation rate. Widely used in tableware, food packaging, etc.

The raw materials of aluminum foil lunch boxes are 3 series or 8 series aluminum ingots, which are cold-rolled or hot-rolled into aluminum foil mother rolls with uniform thickness, smooth surface, no pinholes, no dust particles, and no odor. The lunch box is formed by one-time automatic cold stamping using special equipment and molds.

Aluminum foil container specifications:

| Alloy | 3003, 3004, 8011, 8006 |

| Temper | Soft |

| Thickness | 0.0045mm-0.02mm |

| Width | 200-1450mm |

| Length | 100-16000mm |

| Mechanical properties | Tensile strength (UTS): 35 MPA - 100 MPA s elongation ≥0.5% |

| Inner diameter | 76mm/152mm |

| Application | aviation, hotel, fast food, etc. |

Advantages of aluminum foil for food containers:

1. Non-toxic, tasteless, safe and hygienic

2. High and low temperature resistance

3. Good processing performance and easy to form

4. Strong barrier properties

5. Environmentally friendly and recyclable

6. Excellent decorative properties and exquisite appearance