The anti-corrosion coating on the hydrophilic aluminum foil of air conditioners usually uses water-based epoxy coating. The surface of the aluminum foil is coated with epoxy resin and then dried and cured to form a composite material. It has anti-oxidation, high temperature resistance, moisture resistance, etc. Function.

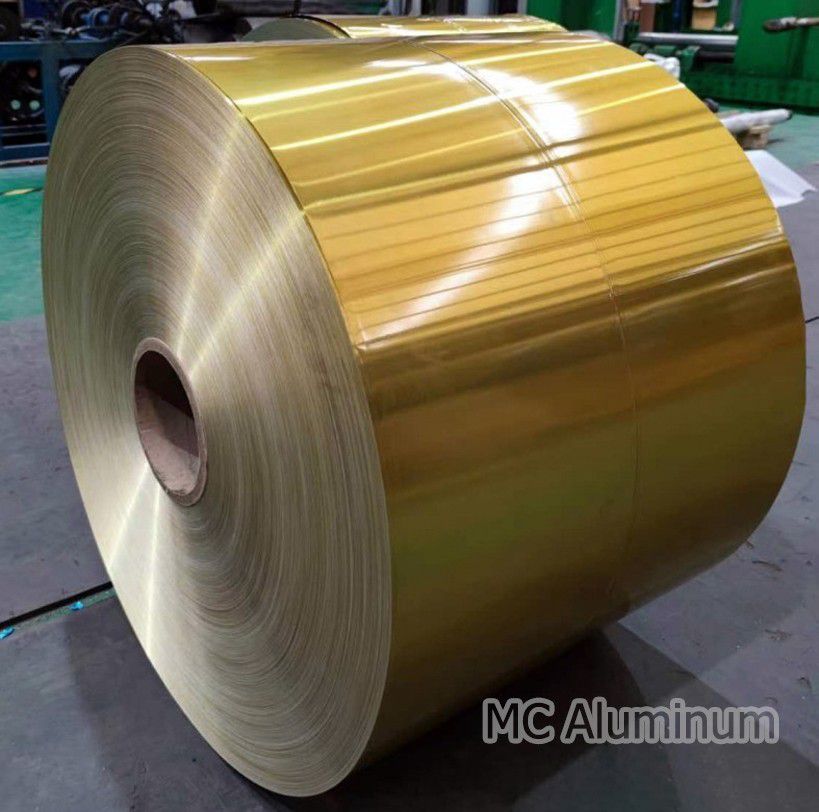

Epoxy coated aluminum foil specifications:

| Alloy | 1050,1100,8011,8079,etc |

| Temper | H16-H18-H22-H24 |

| Thickness | 0.03mm~0.80mm |

| Width | 10-1600mm |

| Coating color | gold |

| Coating weight | 19.5~23.5g/㎡ (total coating amount on both sides) 10% hydrochloric acid + 20% copper sulfate - 24 hours - no corrosion Sodium hydroxide 30%-24 hours-non-corrosive Will not peel under transverse cutting impact Salt spray test time ≥500 hours |

Advantages of epoxy coating on aluminum foil surface:

1. Prevent oxidation: Aluminum foil has good oxidation protection function. After being coated with epoxy resin, it can prevent oxidation even more.

2. High temperature resistance: After aluminum foil is coated with epoxy resin, it can have higher high temperature resistance, usually reaching more than 200°C.

3. Moisture-proof: After the aluminum foil is coated with epoxy resin, it can effectively prevent moisture from intruding, thereby preventing the aluminum foil from being damaged by moisture.

4. Enhanced mechanical strength: After aluminum foil is coated with epoxy resin, the mechanical strength is enhanced and can withstand vibration and impact.