In modern applications across packaging, pharmaceuticals, household use, food, and electronics, the choice of aluminum foil material is critical. Among the many options available, 8011 aluminum foil and 1235 aluminum foilare often compared as two of the most commonly used grades.

Aluminum Foil: 8011 vs. 1235

1. Alloy Composition

8011 Aluminum Foil:

Contains more alloying elements than pure aluminum. The main additives are iron (Fe) and silicon (Si), typically around 0.5–1.0% Fe and 0.5–0.9% Si. These additions improve the strength and mechanical performance of the foil while retaining good ductility and excellent barrier properties.

1235 Aluminum Foil:

Typically contains no less than 99.35% aluminum. The main impurities—iron and silicon—are kept at very low levels (combined Si + Fe content generally below 0.65%). This high purity gives 1235 foil outstanding conductivity, corrosion resistance, and excellent softness and malleability.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 1235 | ≤0.65 | ≤0.05 | ≤0.05 | ≤0.05 | - | ≤0.05 | ≤0.03 | 0.05 | 0.15 | ≥99.45 | |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.15 | 0.1 | 0.08 | 0.05 | 0.15 | Remainder |

2. Mechanical Properties

1235 Aluminum Foil:

Usually produced in the O temper (fully annealed soft state), it offers superb flexibility, elongation, and plasticity. Its tensile strength is relatively low, but it is highly formable, resistant to cracking or pinholes—ideal for deep-drawing and complex forming processes.

8011 Aluminum Foil:

Available in various tempers such as O, H14, H16, H18, H22, and H24, allowing its mechanical properties to be customized. Under the same annealing conditions, 8011 typically has higher tensile strength than 1235. This makes it better suited for applications requiring greater strength or puncture resistance. It also maintains good flexibility for embossing or deep-drawing without cracking.

3. Application Fields

8011 Aluminum Foil:

Widely used in food packaging, including meat, dairy products, coffee, tea, chocolate, and ice cream. It is also used for heat-sealing foil, container foil, aluminum foil liners, and pharmaceutical packaging. Additionally, 8011 is common in tape manufacturing.

1235 Aluminum Foil:

Used in baking trays, coffee packaging, and due to its excellent conductivity and processability, in cables, adhesive tapes, and battery foil applications.

4. Price & Market Position

8011 Aluminum Foil:

Generally priced higher due to its superior performance and broader application range. Demand in the market is strong.

1235 Aluminum Foil:

More affordable, making it suitable for price-sensitive applications while still offering excellent performance in its domain.

Conclusion

Both 8011 and 1235 aluminum foils have their own advantages. When choosing between them, businesses should consider the specific use case, performance requirements, and budget constraints to make an informed decision.

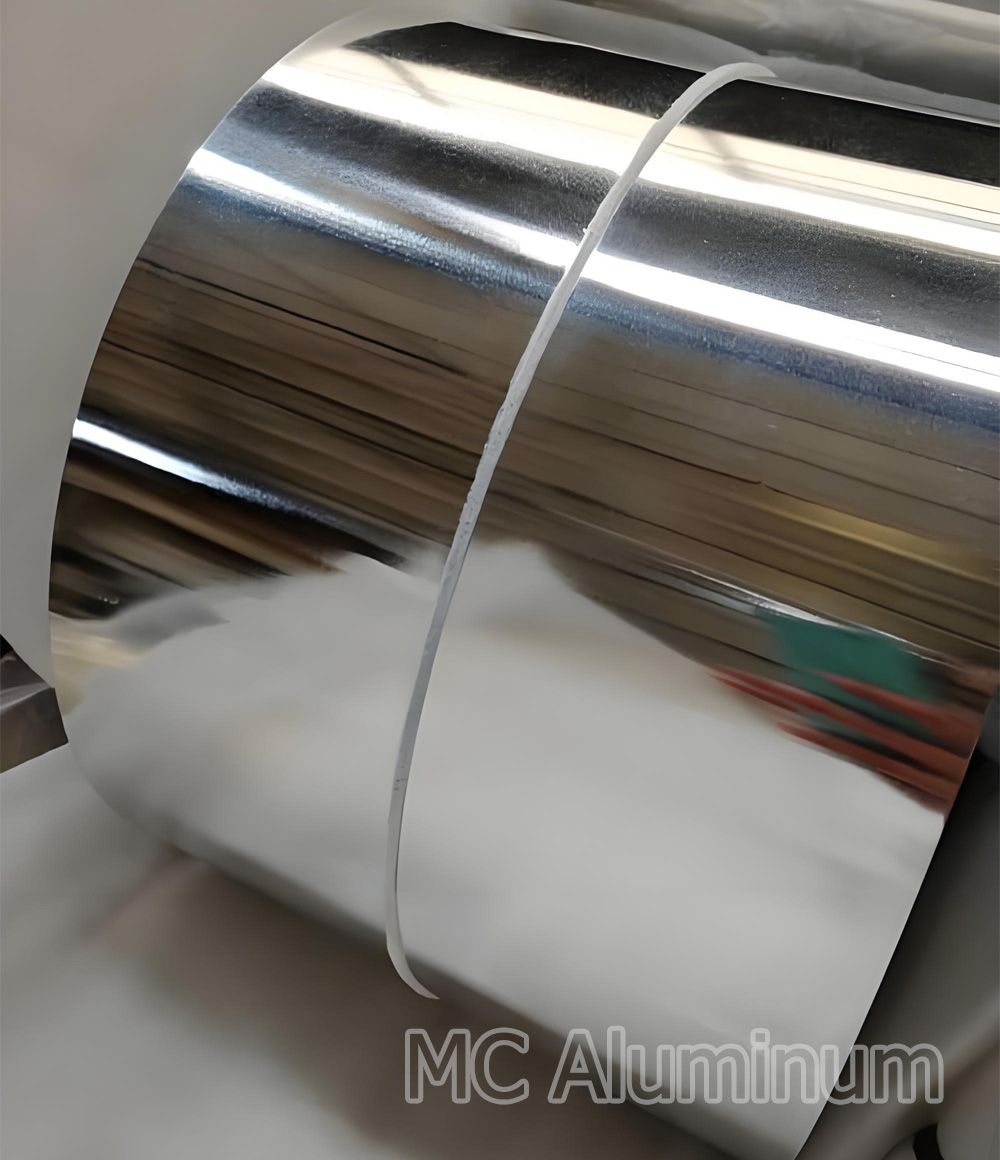

MC Aluminum is a leading aluminum foil manufacturer, offering both 1235 and 8011 aluminum foils with multiple advantages such as clean degreased surfaces, minimal pinholes, excellent flatness, precision slitting without deformation, and burr-free edges. Our products are exported to numerous countries and regions, with direct factory sales, short lead times, and competitive pricing.