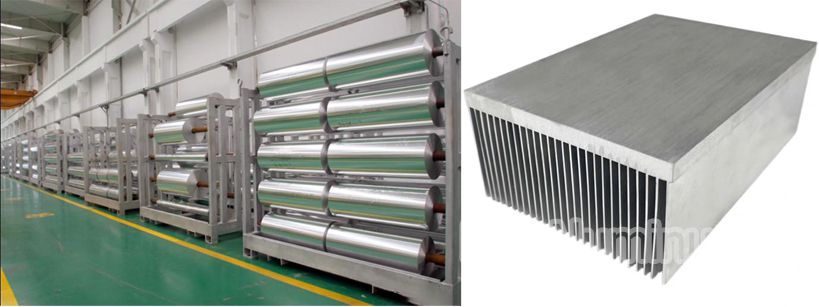

The aluminum foil commonly used in radiator heat exchangers is an extremely thin metal sheet with a thickness range of only 0.006 to 0.2 mm (or 0.0024 to 0.0079 inches). This aluminum foil is often used to replace copper or lead in heat exchange technology, mainly because of its excellent heat resistance and heat dissipation ability. This makes aluminum foil an indispensable and important part of heat exchanger design.

Aluminum foil for radiator usually uses high-purity lightweight aluminum, such as 1050, 1060, and 1100 aluminum alloys. Aluminum foil has high conductivity and corrosion resistance, and can maintain excellent performance under high temperature and high pressure environments. Aluminum foil can quickly transfer heat and improve the efficiency of the heat exchange system. At the same time, it can resist complex metal compounds, chemicals and electrical high-frequency radiation, and extend the service life of the heat exchanger. It is widely used in the top lining part of the heat exchanger.

The width of aluminum foil used in heat exchangers is between 50 and 600 mm, which can meet various specifications and design requirements. MC Aluminum can adjust the width of aluminum foil according to product requirements, add rust inhibitors to enhance anti-corrosion performance, and ensure stability and efficiency in harsh environments.

Features of aluminum foil for radiators:

1. Good thermal conductivity

2. Light weight

3. Corrosion resistance

4. Strong plasticity

5. Low cost

6. Green and environmentally friendly

Aluminum foil radiators are widely used in electronic equipment (such as computers, mobile phones, tablets), household appliances (such as air conditioners, refrigerators) and the automotive industry (such as engine radiators, oil coolers).

In short, aluminum foil for radiators has become an irreplaceable key material in modern heat exchange technology due to its high purity, excellent thermal conductivity, excellent corrosion resistance and light weight. Through strict quality control and advanced production technology, the surface of aluminum foil is clean, flat, free of defects such as oil spots, wrinkles, dark lines, horizontal stripes, black spots, uneven brightness, etc. The products are exported to many countries overseas, directly sold by the manufacturer, and the price is favorable.