In the past, the packaging material of chocolate was usually tin foil packaging. With the continuous improvement of people's economic level and living standards, more and more attention has been paid to the quality of life and health requirements, so chocolate packaging has gradually become aluminum foil packaging. Today's chocolate packaging commonly uses 8011 aluminum foil, which is manufactured by vacuum coating technology. This packaging has low cost, simple processing and stable performance, and is favored by many food manufacturers.

Because chocolate melts easily and spoils easily, if you want to keep it for a long time, you must keep it in a place with a suitable temperature, and avoid sunlight, water and odors. The use of aluminum foil packaging can simultaneously play the role of sealing, moisture-proof, light-proof and thermal insulation, so that the taste of chocolate is not affected by the outside world.

Properties of Aluminum Foil for Chocolate Packaging

1. Clean, uniform in color, no spots, flat and no holes.

2. Non-toxic, tasteless, safe and hygienic.

3. It has excellent moisture resistance and high barrier ability, and can be shaded.

4. Strong mechanical properties.

5. Environmentally friendly and recyclable

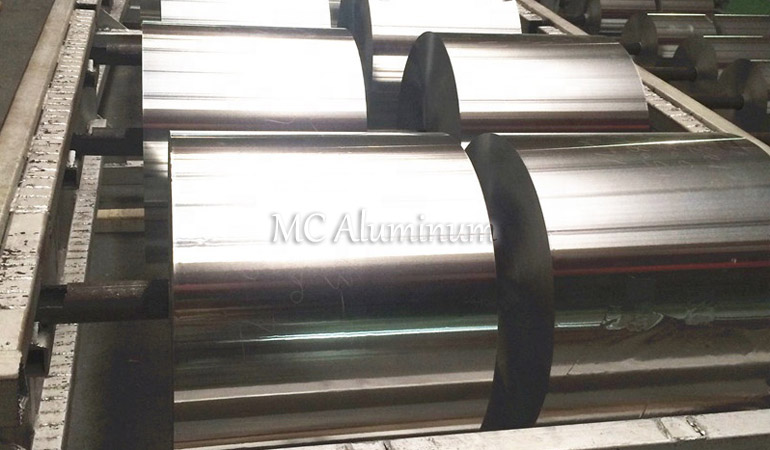

MC Aluminum is a large-scale aluminum foil manufacturer with advanced equipment and strong productivity. It specializes in the production of 1, 3, 5, and 8 series aluminum foil, which can be customized according to customer needs and can provide you with the latest aluminum foil quotation. If you have needs, please contact us!