The aluminum honeycomb panel is mainly composed of fluorocarbon paint coating, aluminum panel surface, aluminum honeycomb core, aluminum bottom plate, protective back coating and special glue. Aluminum honeycomb panels can also be pasted and compounded with fireproof boards, stone materials, and ceramics.

Fluorocarbon resin coating, mainly sprayed on the panel of aluminum honeycomb panel, is used to resist the test of external environment. Fluorocarbon resin has a stable chemical structure and can resist the erosion of various environments, including wind, sun, rain and snow The intrusion of weather and corrosive substances.

The aluminum alloy panel is made of high-quality aluminum alloy sheet, and the thickness is usually between 0.8-1.5mm. For aluminum honeycomb panels, aluminum alloy panels are generally not selected for 1-series aluminum alloys, and 3003-H24 and 5052-H14 are often selected by manufacturers.

The aluminum base plate, similar to the panel, usually also chooses an aluminum alloy model with excellent quality. The bottom plate only needs to undergo a simple anti-oxidation treatment to resist corrosive substances in the air. This is also the so-called protective back coating. Usually, in order to save costs, the manufacturer does not spray paint on the back, except for the special requirements of customers.

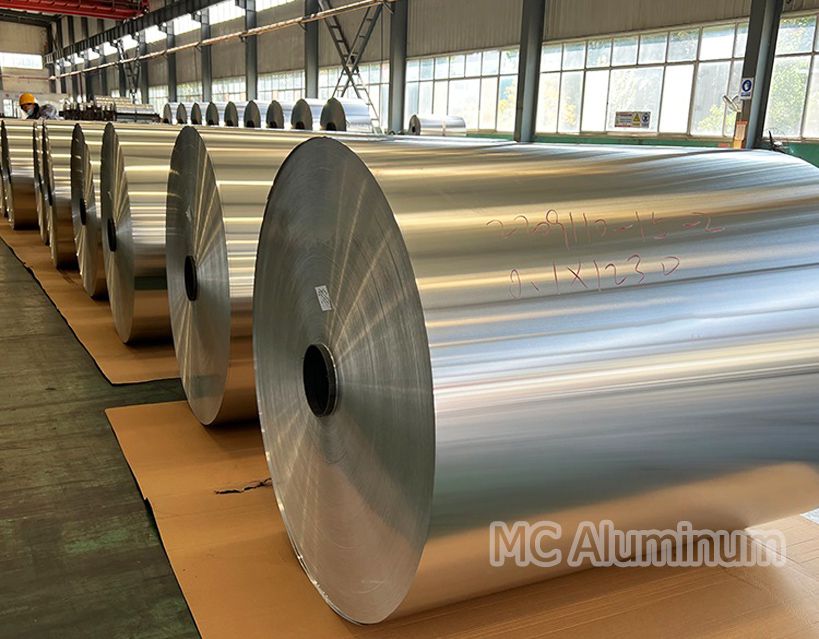

MC Aluminum specializes in the production of aluminum sheets, aluminum foils and other products, with rich production experience, advanced technical equipment, skilled production technology and perfect after-sales service. The product models are complete, and the surface has the advantages of clean oil removal, high strength, and flat plate shape. It is exported to many overseas countries and regions, providing high-quality aluminum plate products for domestic and foreign customers.