Coated aluminum foil for heatseal lids refers to a product that uses a specific process to coat one or more functional coatings on the surface of aluminum foil to improve the heat-sealing performance, barrier performance, mechanical properties, etc. of the aluminum foil to meet specific packaging needs. It is mainly used to make various packaging covers that require heat sealing, such as yogurt covers, dairy product covers, medicine bottle covers, etc.

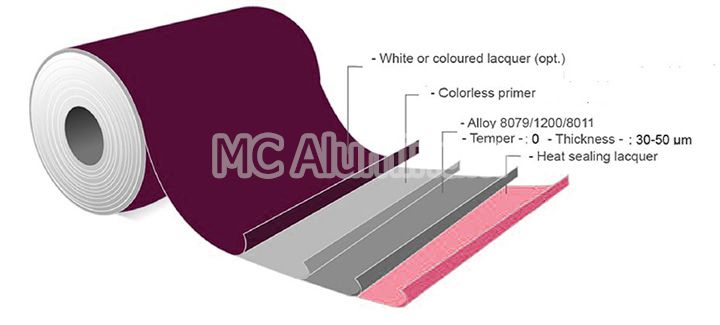

heatseal aluminum foil covers usually use 8011 aluminum foil, 8079 aluminum foil, etc., and then carry out coating, drying, curing and other steps.

heatseal aluminum foil is a commonly used food packaging material, and its unique properties enable it to maintain the freshness and quality of food. When heat sealing, a certain temperature and time are required to complete. Generally, heatseal aluminum foil needs to be sealed at a temperature of 120℃-180℃.

Coated aluminum foil for heatseal lids has multiple performance advantages:

1. Excellent heat-sealing performance to ensure packaging sealing.

2. Good barrier properties to prevent external factors from affecting the product.

3. Strong mechanical properties, meeting various packaging needs.

4. Safe and hygienic, in line with food hygiene standards.

Aluminum foil cover specifications:

| Alloy | 8011/8079 |

| Temper | O |

| Width | Customized (100mm-800mm) |

| Thickness | 0.03-0.05mm. |

| Length | C |

| Structure | Printing primer/aluminum foil/HSL |

| Heat seal | PP, PS, PE, PET, PVC, etc. |

| ID | 76/152mm |

| OD | Customized |

| Application | dairy packaging cover, butter packaging cover, jam packaging cover, etc. |

| Heat seal coating | |

Can contact with food. Waterproof (30 minutes at room temperature). Boiling water resistant (5 minutes/100℃) Coating porosity (15 minutes) <5 holes/m2 (20g CuSO4/50CC HCL (35%)/1000CC.H2O) (Anti-corrosion coating can withstand this test for up to 2 hours). | |

| There are different types of lids, depending on the material they have to seal against | |

| Heatsealing lacquer to PS/PVC | Peel strength to PS> 5.5N/15mm.(180℃, 40kg, 1s) Peel strength to PVC> 9N/15mm.(180℃, 40kg, 1s) |

| Heatsealing lacquer to PVC | Peel strength to PVC> 9N/15mm.(180℃, 40kg, 1s) |

| Heatsealing lacquer to PE | Peel strength to PE> 9N/15mm.(200℃, 40kg, 1s) |

| Heatsealing lacquer to PP | Peel strength to PVC> 9N/15mm.(200℃, 40kg, 1s) |

| Heatsealing lacquer to PP/PS/PVC/PET | Peel strength to PP> 9N/15mm.(200℃, 40kg, 1s) Peel strength to PVC> 9N/15mm.(180℃, 40kg, 1s) Peel strength to PS> 9N/15mm.(180℃, 40kg, 1s) Peel strength to PET> 9N/15mm.(200℃, 40kg, 1s) |