The core value of PTP aluminum foil lies in its “metallic crystal structure”—aluminum atoms are densely arranged to form a natural barrier, completely blocking oxygen, moisture, and ultraviolet rays. This structural advantage extends the shelf life of tablets by more than 30%, making it an irreplaceable material in pharmaceutical packaging.

PTP aluminum foil is typically used as the lidding foil in blister packaging, paired with thermoformed rigid plastics such as PVC, PVDC, PET, PP, or cold-formed aluminum (Alu-Alu). Its typical structure includes the following layers:

Typical Structure of PTP Aluminum Foil

Outer Protective Layer / Printing Primer (Optional Primer/OP Layer):

A thin protective coating or primer layer that enhances printability and protects printed designs from abrasion. It also carries critical drug information, brand logos, and batch numbers.

Aluminum Foil Layer (Aluminum Foil):

The core functional layer of the PTP structure, typically made of hard or semi-hard pure aluminum foil with a thickness ranging from 20 to 30 microns. The aluminum layer provides exceptional barrier properties.

Heat-Seal Layer (Heat-Seal Lacquer/HSL):

This layer bonds directly to the blister base materials. During packaging, heat and pressure activate the adhesive to securely seal the aluminum foil to substrates such as PVC or PVDC, creating sealed cavities to protect each tablet.

Heat Seal Parameters

Heat Seal Parameters

| Item | Recommended Range |

| Sealing Temperature | 180~220°C |

| Sealing Pressure | 0.2~0.4 MPa |

| Sealing Time |

Various Opening Styles

| Type | Structural Characteristics | Application Scenario |

| Press-through | Protective Layer / AL / HSL | Standard tablets (used in 90% of China market) |

| Peelable | PET / AL / HSL | Pressure-sensitive drugs (e.g., sustained-release pellets) |

| Peel-Push Hybrid | Paper / PET / Adhesive / AL / HSL | Child-resistant packaging (mainstream in Europe and USA) |

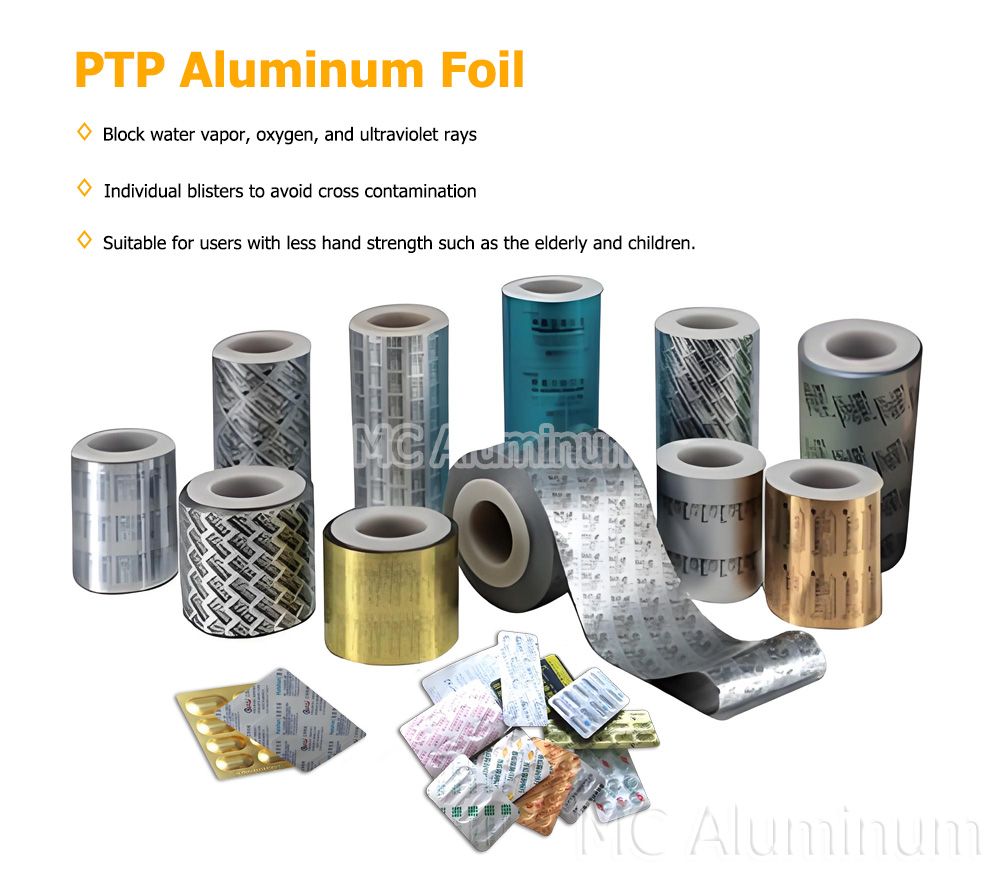

Core Functions of Medical Packaging PTP Aluminum Foil

1.Excellent Barrier Properties:

Blocks light, oxygen, moisture, and microbes, maximizing drug stability and shelf life.

2.Accurate Dosage & Convenience:

Each blister unit isolates one tablet, ensuring accurate dosing and improving patient compliance.

3.Physical Protection:

Prevents damage from compression or breakage during transportation and storage.

4.Hygiene and Safety:

Individually sealed units eliminate cross-contamination risks and maintain sterility before opening.

5.Easy Opening (Press-through):

Users can easily press tablets out of the foil, offering simple and convenient access.

6.Information Carrier:

Enables printing of essential information such as drug name, dosage, expiration date, and batch number.

7.Anti-Counterfeiting Features:

Printed designs and special surface treatments add a layer of authenticity and tamper evidence.

PTP Aluminum Foil Innovations

Child-Resistant (CR) & Senior-Friendly (SF) Design:

A major innovation trend in PTP foil. By using tougher foils, advanced piercing structures, or multilayer composites, packaging becomes harder for children to open accidentally while remaining easy for seniors or patients with limited hand strength.Smart Identification Codes:

Printed or integrated codes and complex holograms on aluminum foil allow for unique drug traceability ("one item, one code") throughout the supply chain and help combat counterfeit products.

MC Aluminum's PTP Foil Quality Control Measures

1.Raw Material Inspection:

Strict control of foil thickness, pinholes, mechanical strength, protective and sealing layers.

2.Printing Quality:

Ensures image clarity, accurate color reproduction, registration precision, and low solvent residues.

3.Heat Seal Performance:

Sealing strength is a critical index. The foil must reliably bond with blister substrates under recommended conditions.

4.Migration Testing:

Ensures no harmful substances migrate from the packaging into the drug, complying with pharmaceutical packaging regulations (e.g., EU Regulation (EC) No 1935/2004, US FDA CFR Title 21).

5.Production Environment:

PTP aluminum foil is produced and slit in cleanroom environments to prevent contamination.

MC Aluminum is a manufacturer of raw aluminum foil materials for PTP pharmaceutical packaging (not involved in adhesive or composite processes and not supplying finished foil products). The company produces 8011 aluminum foil, 1060 aluminum foil, and more—offering high cup-convex value, strong sealing performance, no pinholes, and excellent tightness—making MC Aluminum a trusted raw material supplier for pharmaceutical packaging manufacturers in both domestic and international markets.