Drugs are supplies related to human life safety. The quality of drugs is a topic of social concern and a requirement that many manufacturers are constantly pursuing for continuous improvement. Among them, the selection of aluminum foil for pharmaceutical packaging materials is an important physical monitoring indicator related to the quality of pharmaceuticals. There are two types of pharmaceutical aluminum foil commonly used: aluminum blister foil (PTP foil) and aluminum-aluminum cold-formed foil (PE/AL/PVC), which are the main materials for pharmaceutical packaging. This product can completely protect against the effects of steam, oxygen and ultraviolet rays on medicinal properties.

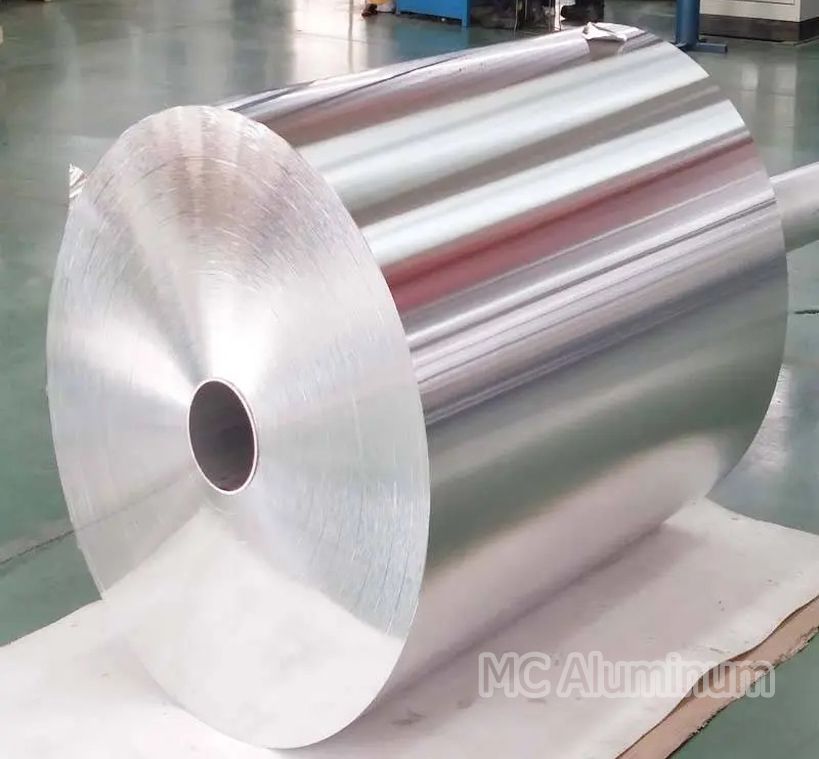

The aluminum foil alloys produced by MC Aluminum for pharmaceutical packaging are 8011 aluminum foil, 8021 aluminum foil, 8079 aluminum foil, etc. The product status is O, H14, H16, H18, etc., and the product thickness is between 0.016-0.2mm. The product is food grade aluminum foil, with It has the advantages of flat plate shape, grade A brushing, high cupping value, and few pinholes. It is widely used in ptp capsule medicine plates, blister packaging, tropical blister packaging, pharmaceutical bottle caps and other fields.

Performance advantages of pharmaceutical aluminum foil:

1. It has good moisture and oxygen barrier properties, and is sealed with the molding material to avoid light and have high barrier properties;

2. The protective layer has excellent high temperature resistance, and the adhesive layer has good heat sealing performance. It can be heat-sealed with composite sheets such as PVC, PVDC, and molding materials, and has good sealing performance;

3. It is easy to push open or puncture, making it convenient for consumers to take. The packaged blister board is easy to carry, easy to transport, store and prevent contamination;

4. High-precision printing, rich colors and clear patterns. Plain foil can be printed online on automatic pharmaceutical blister packaging machines.

MC Aluminum is an aluminum foil manufacturer specializing in the production of medical aluminum foil. The surface is clean, flat, and evenly coated. There are no dense, continuous, and periodic pinholes. The content of heavy metals does not exceed 0.25 parts per million. Complies with pharmaceutical aluminum foil standards. The product models are complete and can be customized according to customer needs. We can provide sample mailing services and are sold overseas. After-sales service is guaranteed. Customers can order with confidence and look forward to your contact.