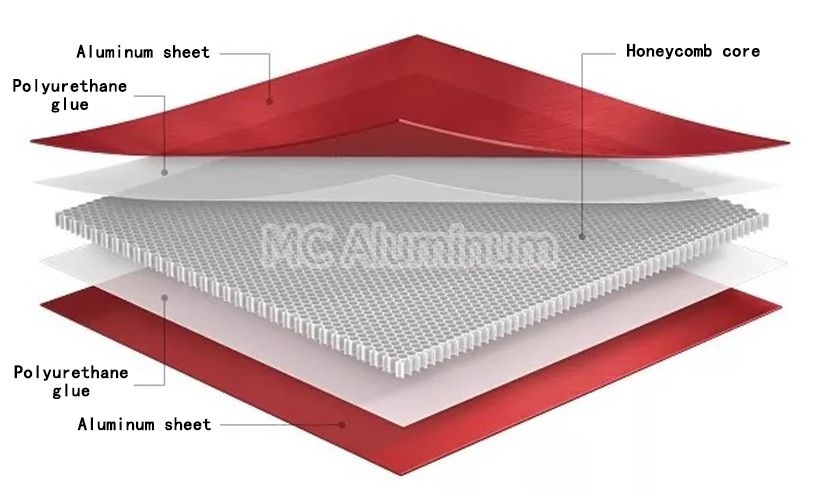

The aluminum honeycomb core is made by bonding multiple layers of aluminum foil, and then unfolded into a regular honeycomb shape. The factors that affect the performance of the honeycomb core material mainly include parameters such as aluminum foil, node glue, and honeycomb core specifications. Aluminum foil is one of the important materials, and its performance has an impact on the quality and service time of the honeycomb core. The aluminum honeycomb core is processed and produced with a hexagonal honeycomb core material made of 3003 aluminum foil/5052 aluminum foil.

The aluminum honeycomb core is a hexagonal honeycomb core made of aluminum foil, the thickness of the aluminum foil is 0.02~0.06mm, and the aluminum honeycomb side length models are 5mm, 6mm, 8mm, 10mm, 12mm, etc.

Advantages of aluminum foil for honeycomb core:

1. It is made of metal, so it is easy to recycle and is a green product;

2. Light weight, high strength, good rigidity and tear resistance;

3. Excellent weather resistance: high temperature resistance, corrosion resistance, aging resistance;

The surface of the honeycomb material is degreased with 3003 aluminum foil, and the glue is not easy to fall off. The special degreasing equipment uses imported cleaning fluid to ensure that the surface of the aluminum foil is free of oil, the glue is firm, not easy to fall off, and the use time is long.

MC Aluminum is a professional manufacturer of aluminum foil, including aluminum foil for honeycomb core. The base material of aluminum foil is flat, and there are no defects such as black spots, small black wires and bright lines, and there are no burrs, flounces and rummaging that affect the quality of slices. The quality is guaranteed.(MC Aluminum only produces aluminum foil substrates for honeycomb cores, and does not provide finished products.)