Aluminum blister foil (commonly known as Ptp blister aluminum foil) is a composite material commonly used for pharmaceutical packaging. This form of packaging is to fill the drug into the groove after the transparent plastic hard sheet is blister-formed, and then heat and bond it with the aluminum foil sheet coated with adhesive to form an independent sealed package. The structural design of the blister aluminum foil is designed to provide excellent barrier properties, mechanical strength and corrosion resistance to protect the quality and safety of the drug.

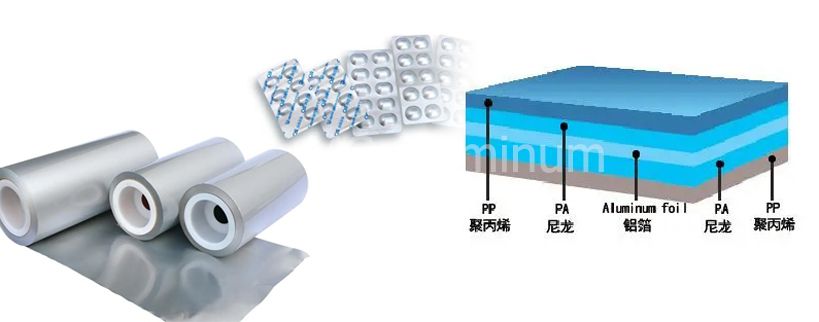

Structural hierarchy of aluminum blister foil:

1. Protective layer (OP)

Material: Printing layer or transparent protective film (such as BOPP, PET, etc.).

Function: Protect the lower layer material, provide printed patterns and information display, and enhance the aesthetics and brand recognition of the packaging.

2. Aluminum foil layer

Material: 8011 aluminum alloy or other suitable aluminum alloy.

Thickness: Usually between 20 and 30 microns.

Function: Provide high barrier properties, prevent the penetration of oxygen, water vapor and light, and protect drugs from the external environment.

3. Adhesive layer (VC)

Material: Adhesive (such as epoxy resin, polyurethane, etc.).

Function: Bond the aluminum foil layer with the heat seal layer to ensure the firm bonding of the layers.

4. Heat seal layer (inner layer)

Material: Usually heat seal materials such as PVC, PVDC, PP, PE, etc.

Function: Heat seal with blister packaging materials to ensure the sealing of the packaging and prevent drugs from being damp or contaminated.

PTP blister aluminum foil characteristics:

1. The high barrier properties of aluminum blister foil can extend the shelf life of drugs.

2. The composite structure provides good mechanical properties and is suitable for high-speed automated packaging equipment.

3. The aluminum foil layer has good corrosion resistance, which can ensure the long-term storage of drugs.

4. Printability facilitates drug information identification and brand display.

5. Good heat sealing performance prev