3102 air conditioning foil is a high-performance aluminum alloy foil specially developed for manufacturing air conditioner heat exchanger fins (fin stock). It features excellent thermal conductivity, corrosion resistance, formability, and mechanical strength, significantly improving the heat exchange efficiency and service life of air conditioners.

3102 belongs to the aluminum-manganese series (Al-Mn) wrought aluminum alloys. Its primary alloying element is manganese (Mn), with small amounts of copper (Cu) and silicon (Si), ensuring excellent corrosion resistance and formability. It is currently a mainstream eco-friendly raw material for air conditioning fins.

Chemical Composition of 3102 Aluminum Foil

| Element | Content (%) |

| Mn | 0.05-0.20 |

| Cu | ≤ 0.10 |

| Si | ≤ 0.70 |

| Fe | ≤ 0.70 |

| Mg | ≤ 0.05 |

| Zn | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Al | Remainder |

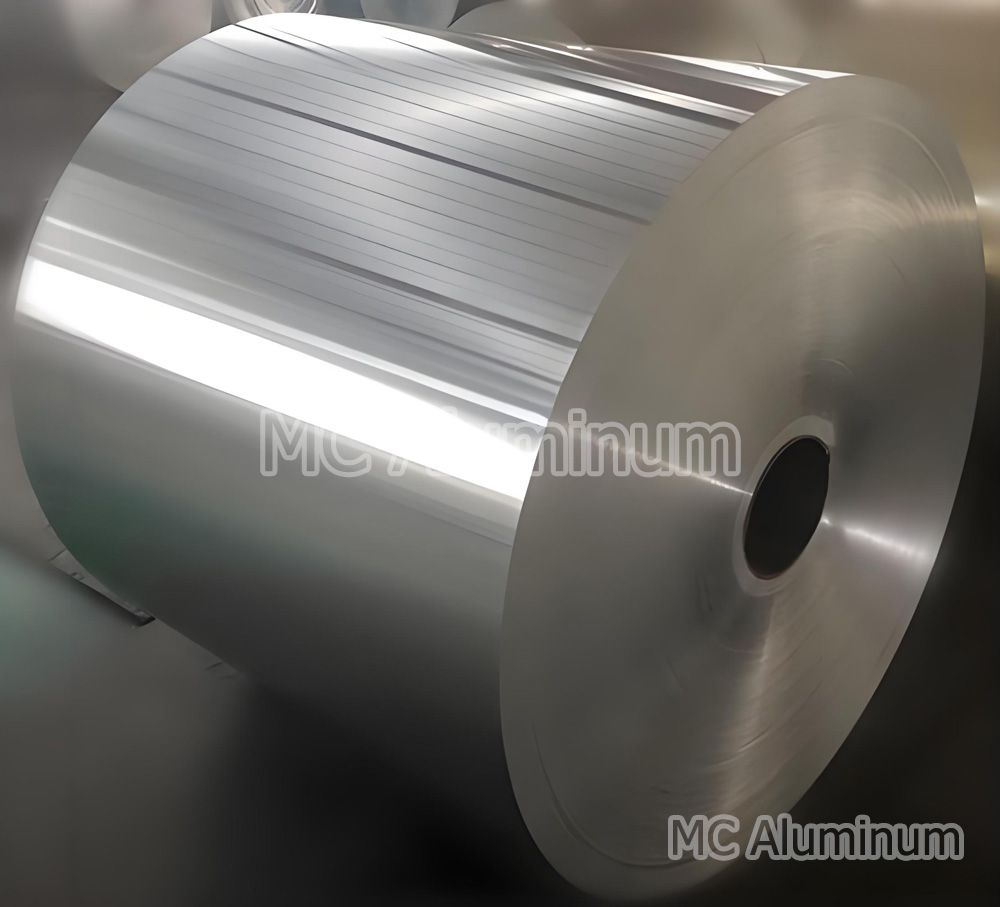

Product Information

| Alloy | 3102 |

| Thickness | 0.008mm - 0.2mm |

| Width | 250mm - 1650mm |

| Temper | HO / H22 / H24 / H26 / H18, etc. |

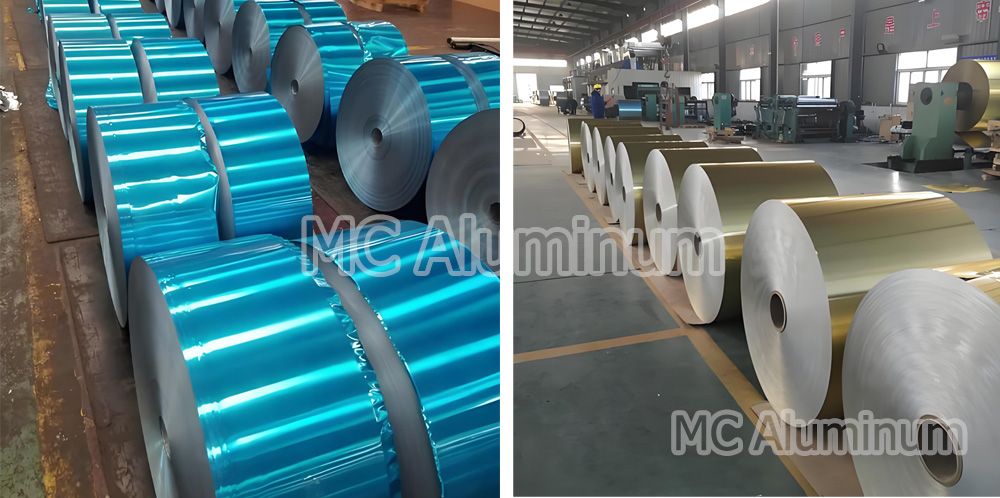

| Coating Colors | Gold, Blue |

| Surface Treatment | Hydrophilic, epoxy resin, etc. |

| Industry Applications | Air conditioner fin stock, hydrophilic foil, heat-dissipating aluminum foil, etc. |

Why Use 3102 Aluminum Foil in Air Conditioners?

Foil made from 3102 alloy plays a vital role in the effective operation of HVAC (Heating, Ventilation, and Air Conditioning) systems. Here's why:

1.Heat Exchange Efficiency

The main function of aluminum fins is to significantly increase the surface area of the heat exchanger (condenser and evaporator coils), enabling more efficient heat transfer between the refrigerant and air.

2.Lightweight

Aluminum is lightweight, helping to reduce the overall weight of the air conditioning unit, making it easier to transport and install, and potentially improving energy efficiency.

3.Corrosion Resistance

Air conditioning units are exposed to moisture (condensation) and various atmospheric pollutants, which may lead to corrosion. 3102’s excellent corrosion resistance helps extend the service life of the heat exchange components.

4.Cost Efficiency

Aluminum is a relatively abundant and cost-effective material, making it ideal for large-scale production of AC units.

5.Surface Coating Options

3102 aluminum foil is commonly treated with specialized coatings for enhanced performance:

(1) Hydrophilic Coating

Allows condensation to spread evenly and drain smoothly rather than forming droplets that block airflow and reduce heat exchange. This improves efficiency and lowers noise.

(2) Hydrophobic Coating

Less common in standard AC fins, but used in specific dryer or dehumidifier applications to prevent water from clinging to surfaces.

3102 Aluminum Foil Surface Treatment Options

3102 aluminum foil can be customized with the following surface treatments based on customer requirements:

Hydrophilic coating: Prevents water droplet buildup, enhances heat transfer, widely used in mid-to-high-end air conditioners.

Anti-corrosion coating: Extends service life, suitable for coastal or acidic environments.

Embossed surface: Increases rigidity and surface area, improves airflow.

Bare foil: For further deep processing or special-purpose applications.

Application Fields of 3102 Aluminum Foil

Household air conditioner and central air conditioning heat exchanger fins

Refrigerator evaporators and condensers

Automotive air conditioning evaporators/condensers

Heat pump system heat exchangers

Industrial refrigeration and cooling equipment components

MC Aluminum – Comparison of Foil Types and Use Cases

3102 Aluminum foil :Lower electrical resistivity; ideal for large condensers used in high-temperature and high-humidity environments. Can be combined with various alloys for improved performance.

8011 Aluminum foil :Made from high-quality aluminum; reduces resistance in condensers/evaporators, ensuring proper cooling system function. More affordable than 3102, suitable for small condensers and car air conditioners.

1100 Aluminum foil :Excellent thermal conductivity and corrosion resistance; lower cost, widely used in all types of air conditioners.

1060 Aluminum foil :Best suited for small AC units and electronics radiators; excellent weldability and formability, customizable for different needs.

As a professional aluminum foil manufacturer, MC Aluminum produces air conditioning foil using typical alloys such as 3102, 8011-H22/H24/H26, with thicknesses ranging from 0.08mm to 0.2mm. The foil has flat profiles, is free from oil, black lines, scratches, or burrs. Our products are exported to multiple countries and regions worldwide. Samples are available, delivery is fast, and our production capacity is extensive — giving you confidence in placing orders with us.