Aluminum foil for packaging Aluminum foil for packaging is one of the uses of aluminum foil. Because aluminum foil has a series of good properties, its application range is very wide, and the demand for aluminum for packaging is the largest. These products are suitable for moisture-proof, light-proof and vacuum packaging of large-scale precision mechanical equipment, chemical raw materials, and pharmaceutical intermediates. The four-layer structure is mostly used, which has good water and oxygen barrier functions. There is no limit, and packaging bags of different specifications and styles can be customized, and can be made into flat bags, three-dimensional bags, organ bags and other styles.

Aluminum foil bag scope of application:

1.Suitable for packaging of various circuit boards, electronic products, precision machinery parts, consumer goods, industrial products, etc. For example: PC boards, IC integrated circuits, electronic components, SMT patches for various LED industries, light bar packaging, precision hardware, auto parts and other packaging.

2.Food packaging: rice, meat products, dried fish, aquatic products, cured meat, roast duck, roast chicken, roast pig, quick-frozen food, ham, cured meat products, sausages, cooked meat products, pickles, bean paste, seasoning, etc. The protection of fragrance, quality, taste and color.

Advantages of aluminum foil for packaging:

1. Strong air barrier performance, anti-oxidation, waterproof and moisture-proof.

2. Strong mechanical properties, high blast resistance, strong puncture and tear resistance.

3. High temperature resistance (121°C), low temperature resistance (-50°C), oil resistance, and good fragrance retention.

4. Non-toxic and tasteless, in line with food and drug packaging hygienic standards.

5. Good heat sealing performance, softness and high barrier performance.

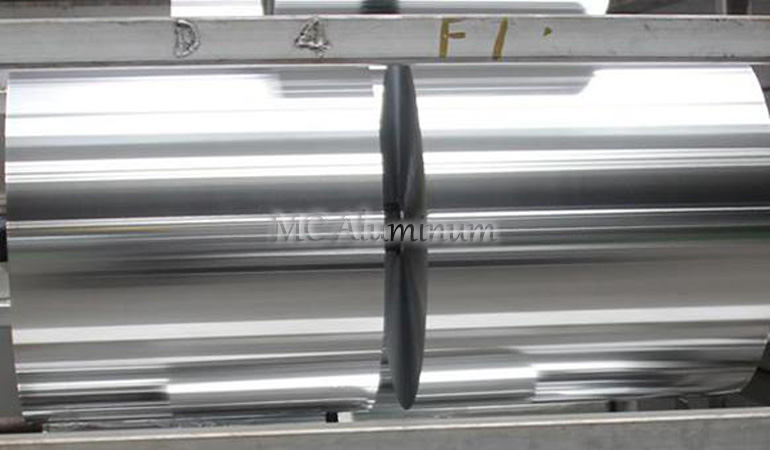

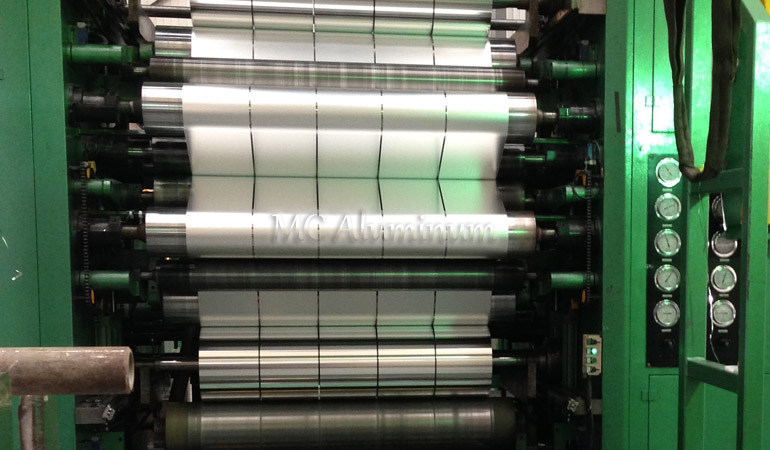

MC Aluminum is a large-scale manufacturer of aluminum foil raw materials for packaging. The raw materials of aluminum foil for aluminum foil bags are mainly 1 series, 3 series and 8 series products, mainly including models 1060, 1100, 3003, 8011, 8021, etc. According to the needs of the packaged products, the degree of softness and hardness of the alloy, that is, the state of the alloy, is selected. The commonly used states are H14, H16 and H18. If you have needs, please contact us, and the account manager will provide you with the best solution and the latest quotation.