Blister packaging for pharmaceuticals, also known as PTP packaging, is widely used for solid dosage forms such as tablets, pills, suppositories, and capsules. It offers advantages such as excellent drug stability, high production efficiency, lightweight design, easy transportation, and convenient dosing for small or serialized packaging.

Since pharmaceuticals are highly sensitive to moisture, oxygen, and light, exposure to humidity can lead to drug degradation and loss of efficacy. To maintain drug potency, blister packaging must provide superior barrier performance.

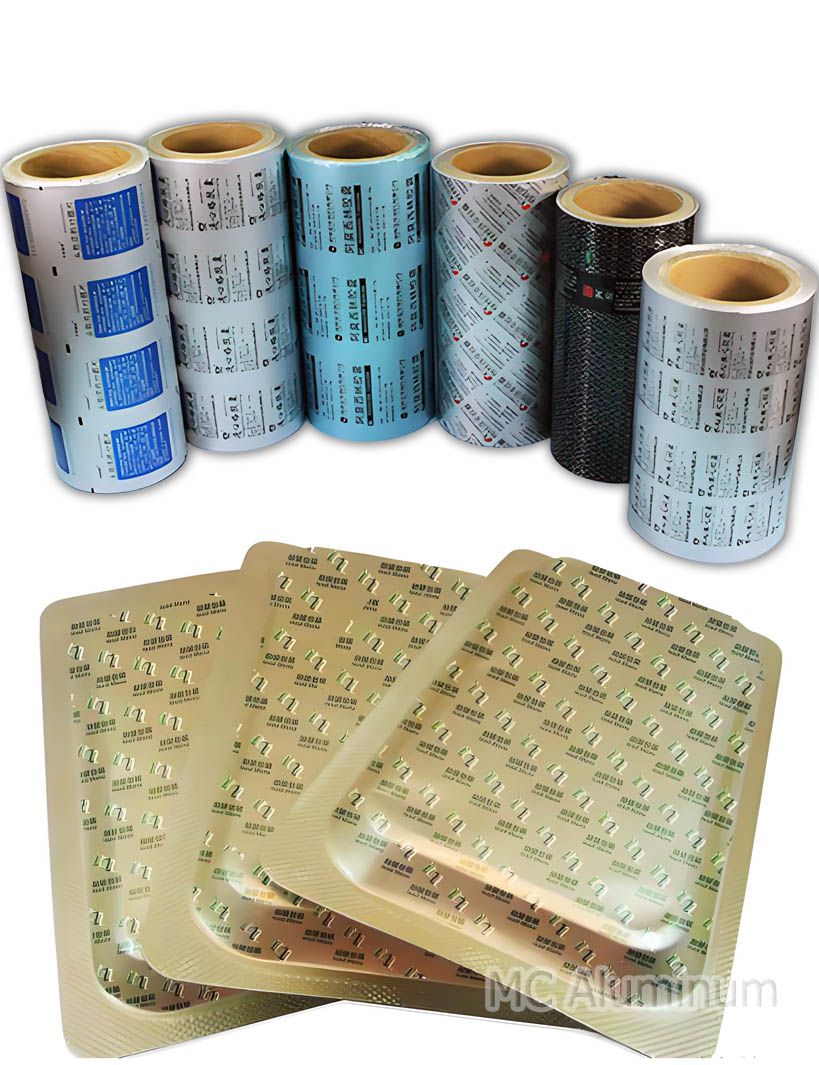

Structure of Tropical Blister Aluminum

Outer Aluminum Foil: Made of 8021 aluminum foil and 8079 aluminum foil, it acts as a barrier against moisture, oxygen, and UV rays, enhancing drug stability.

Inner Heat Seal Coating: Ensures sealing with PVC/PVDC composite sheets and other substrates for airtight protection.

Adhesive Layer: Bonds the aluminum foil to the inner coating, improving durability and overall strength.

Advantages of Tropical Blister Aluminum Packaging

1.Moisture Resistance: Exceptional moisture barrier properties effectively prevent drug degradation due to humidity.

2.Barrier Performance: Provides outstanding protection against oxygen, light, and other gases, preventing oxidation and deterioration.

3.Corrosion Resistance: Maintains stability even in high-temperature and high-humidity environments, protecting pharmaceuticals from external contaminants.

4.Sealing Performance: Excellent heat-sealing properties ensure a secure blister pack, preventing contamination.

5.Mechanical Strength: High durability to withstand processing and handling stresses during packaging and transportation.

Applications

✅ Pharmaceutical Packaging: Widely used for tablets, capsules, and pills, particularly in tropical and subtropical regions where moisture control is critical.

✅ Medical Device Packaging: Suitable for certain medical devices, ensuring sterility and stability even in high-temperature and humid environments.

Comparison: Tropical Blister Aluminum vs. Cold-Formed Aluminum

Tropical aluminum packaging is not a replacement for cold-formed aluminum packaging; instead, it serves as an alternative based on different moisture protection requirements and display preferences.

The key functional difference lies in moisture protection, which in tropical blister aluminum relies on the seal between the edges and the PVC blister. The stability of heat-sealing temperature, smoothness of sealing mold surfaces, and uniform pressure significantly impact the sealing performance.

Thus, in this process, the coating layer of tropical aluminum foil plays a crucial role in ensuring optimal sealing and moisture resistance.