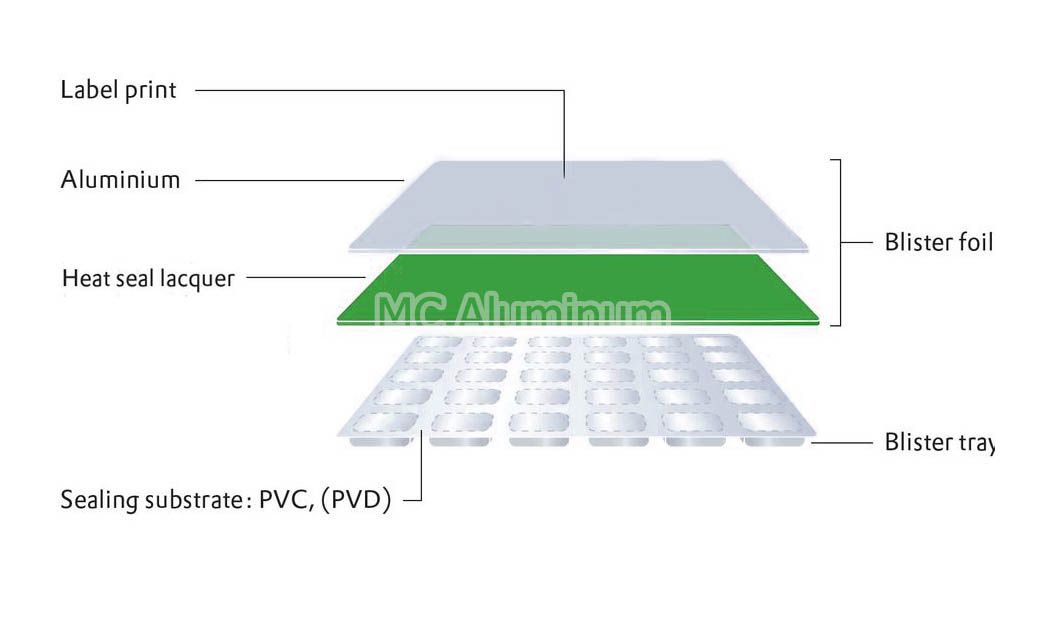

Blister pack is a two-part preformed package consisting of a thermoformed plastic tray and a flexible cap material or a cold-formed tray and cap material. The cap material usually contains aluminum foil and is bonded to the formed tray by heat sealing.

Advantages of blister packing for pharmaceuticals:

1. Protect the quality of pharmaceuticals: Independent packaging can effectively isolate air, moisture and light, prevent pharmaceuticals from moisture, deterioration, oxidation, and extend the shelf life of pharmaceuticals.

2. Convenient to carry and use: Blister packing can intuitively display the remaining amount of medicine, which helps patients take it on time and reduce the situation of missed or accidental ingestion.

3. Improve safety: Some blister packs adopt an anti-tampering design, which increases the difficulty of children opening and reduces the risk of accidental ingestion.

4. Reduce the cost of pharmaceuticals: Blister packing has high production efficiency and can reduce packaging costs.

5. Recyclable materials: Blister packaging materials can usually be recycled to reduce environmental pollution.

6. Wide application: Tablets, capsules, soft capsules and other drugs can be packaged in blister packaging, which is highly adaptable and widely used in the pharmaceutical industry.

The most commonly used aluminum cap thickness:

Blister packaging is usually built in one of four ways: push-in, peel-off, peel-off and tear-off. In order to meet the performance expectations of each packaging type, aluminum foil caps have different flexibility/rigidity, temper and thickness (also known as gauge):

Ultra-light gauge foil is soft tempered with a thickness of 0.006-0.007 mm

Light foil is soft tempered with a thickness of 0.008-0.012 mm

Aluminum strip packaging foil is soft tempered with a thickness of 0.02-0.05 mm

The thickness of aluminum blister cap foil is usually 0.012-0.025 mm

Aluminum cold-formed foil is soft tempered with a thickness of 0.045-0.06 mm

Pharmaceutical blister packaging is consistent with the range of aluminum foil options to create solutions suitable for standard and custom applications. General:

1. Push-in blister packages are constructed so that the drug dose is pushed into the lid. Therefore, hard tempered aluminum is usually used. Soft tempered aluminum is sometimes used, but less commonly. Lids with relatively high puncture strength are sometimes used to achieve a degree of child resistance.

2. Peelable blister package construction enables the drug dose to be dispensed when the lid is peeled off the tray. Lids used for peel-off applications combine aluminum with a paper backing or a paper/PET backing.

3. Peel-off blister packages are constructed so that the drug dose is dispensed by peeling off the combination of the lidding layer and then pushing the drug into the remaining aluminum foil. The peel-off lid is a layered paper/PET/aluminum foil/HSC.

4. A tear-off package construction is used, so the drug dose is dispensed by tearing the package open. The materials used for tear-off packages are paper/PET/aluminum foil/HSC.