Pharmaceutical blister aluminum foil is a high-precision composite packaging material, mainly used for the sealing packaging of pharmaceuticals, health supplements, and food products. It combines barrier properties, printability, and formability to meet the requirements for moisture protection, light shielding, and extended shelf life.

Printed blister aluminum foil generally refers to standard pharmaceutical blister foil (typically made of soft temper 8021 aluminum foil or 8011 aluminum foil) that has been printed with specialized pharmaceutical-grade ink. MC Aluminum uses gravure printing technology, supporting double-sided pattern printing (such as gold or silver) to enhance product recognition.

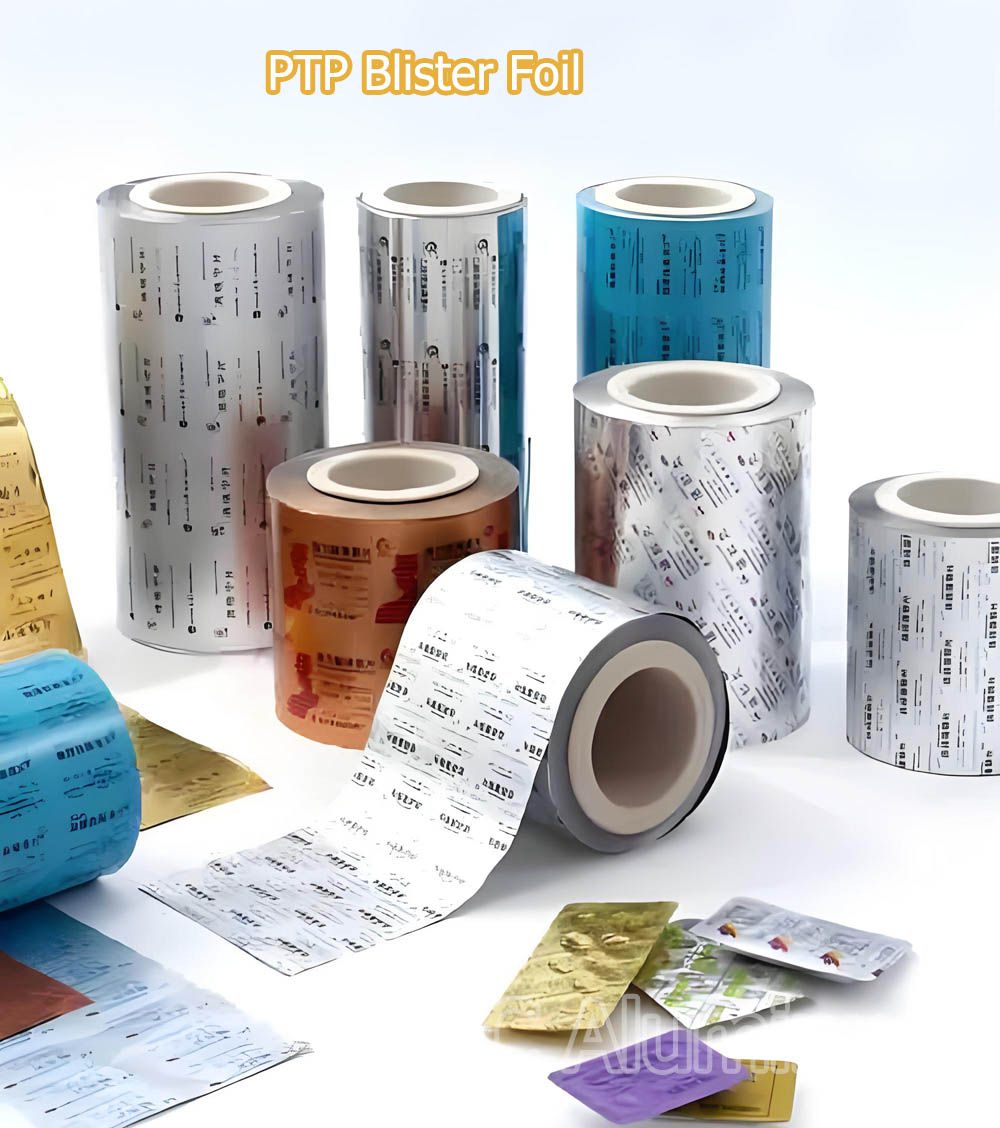

PTP blister foil is primarily used for the blister packaging of solid pharmaceuticals (such as tablets and capsules) and is paired with PVC, PVDC, or cold-form laminated films to create aluminum-plastic blister packaging with excellent sealing performance.

Structure of Printed Blister Aluminum Foil

Printing Layer: Uses specialized pharmaceutical ink featuring abrasion resistance, solvent resistance, non-toxicity, and environmental safety.

Protective Layer (Top Coating): A transparent protective coating that enhances abrasion resistance and ink adhesion.

Aluminum Substrate: Typically made from soft temper 8011-O or 8021-O high-purity aluminum foil, with commonly used thicknesses ranging from 20μm to 30μm.

Bottom Coating: Optional heat-seal coating (such as PVC coating, VC coating, or heat-melt adhesive coating) to facilitate strong bonding with PVC rigid film.

Specifications for Blister Lidding Foil

| Material | 8011-O, 8021-O Aluminum Foil |

| Thickness | 20μm, 25μm, 30μm |

| Width | 100-1600 mm |

| Length | Customized |

| Printing Colors | 1–6 colors customizable (commonly black, blue, red) |

| Coating Type | Heat-seal coating / Protective coating |

| Heat-Sealing Temperature | 160°C–220°C |

| Printing Precision | Capable of fine rendering of text, QR codes, and logos |

Application Fields of Blister Lidding Foil

Pharmaceutical blister packaging (tablets, capsules)

Health supplement packaging (softgel capsules, tablets)

Specialty food packaging (such as oral thin films)

Single-dose cosmetic packaging (such as small facial masks, essence tablets)

Performance Advantages of PTP Blister Foil

1.Excellent Barrier Properties: Completely blocks light, oxygen, moisture, and odors, effectively protecting pharmaceuticals from oxidation or moisture absorption.

2.Outstanding Heat-Sealing Performance: Forms a strong seal with PVC or PVDC films, while allowing easy peelability for patient convenience.

3.Superior Printability: Supports both monochrome and multicolor printing; clear text, vibrant colors, and high resistance to ink peeling.

4.Good Chemical Resistance: Resistant to acids, alkalis, alcohol, and solvents, ensuring stability of the printed surface during storage and use.

5.Hygienic and Safe: Aluminum foil is non-toxic and odorless, meeting pharmaceutical packaging hygiene standards. Its sealing capability prevents moisture absorption, oxidation, or microbial contamination, ensuring medication safety.