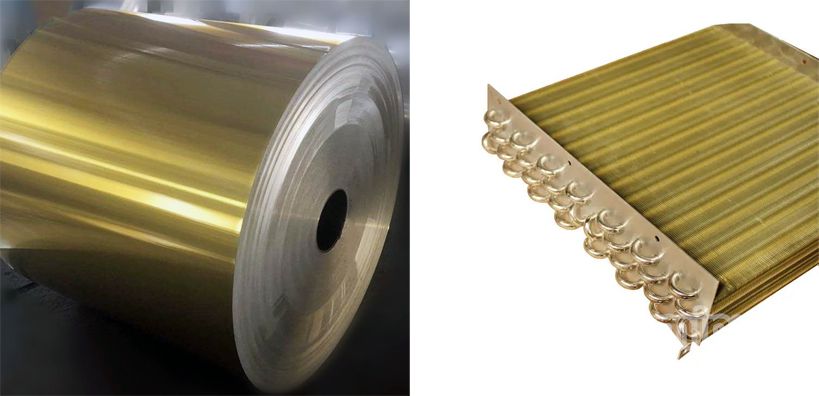

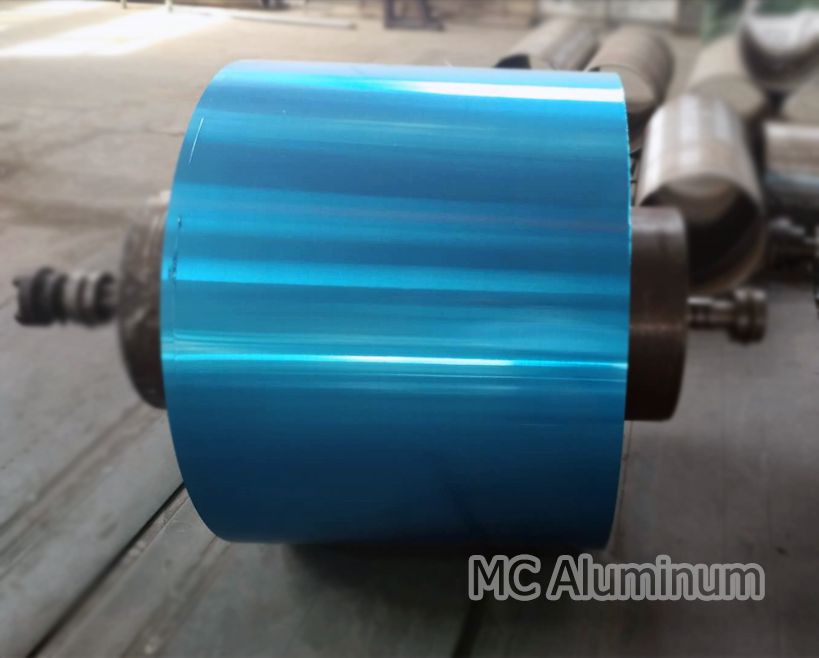

Heat exchanger aluminum foil is an important material used in heat exchangers. It is a new type of aluminum foil product with a density of about 2.6-2.8g/cm³. It is hydrophilic. After special treatment, its special surface coating can make it have better water absorption performance. 8011 aluminum foil and 8006 aluminum foil are used for air conditioning heat exchangers. The common states are 0/HO/H22 and the common colors are Bare/Plain/Blue/Gold. Due to its excellent thermal conductivity and corrosion resistance, it is widely used in air conditioning, car coolers, evaporators and radiators.

8011 and 8006 air conditioning heat exchanger aluminum foils are coated with a hydrophilic layer on the surface of the aluminum foil to increase its corrosion resistance and hydrophilicity. The hydrophilic layer can make the water droplets condensed on the heat exchanger plates in the hot air easily diffuse and flow down along the sheet, avoiding the "bridging" of water droplets between the heat exchanger plates to affect the ventilation effect of the heat exchanger, thereby increasing the heat exchange rate by 10%-15%.

Specifications of hydrophilic aluminum foil for heat exchangers:

| Alloy | 8011, 8006, 3102, 3105, 1100 |

| Thickness | 0.08mm~0.5mm |

| Width | 15mm~1000mm |

| Length | 100~16000mm |

| ID | 75mm, 150mm, 300mm, 400mm, 500mm |

| Color | blue hydrophilic aluminum foil, gold hydrophilic aluminum foil, black hydrophilic aluminum foil, bronze hydrophilic aluminum foil, bare aluminum foil |

| Applications | air conditioners, refrigerators, evaporators, condensers, air conditioner radiators, heat exchangers, etc. |

Advantages of aluminum foil for heat exchangers:

1. Excellent hydrophilicity and corrosion resistance

2. Good formability

3. Strong resistance to stamping oil, solvents and heat resistance

4. Low air flow resistance, heat exchange rate can be increased by 10%-15%

5. Smooth surface and beautiful appearance

6. Extend service life

7. Environmental protection