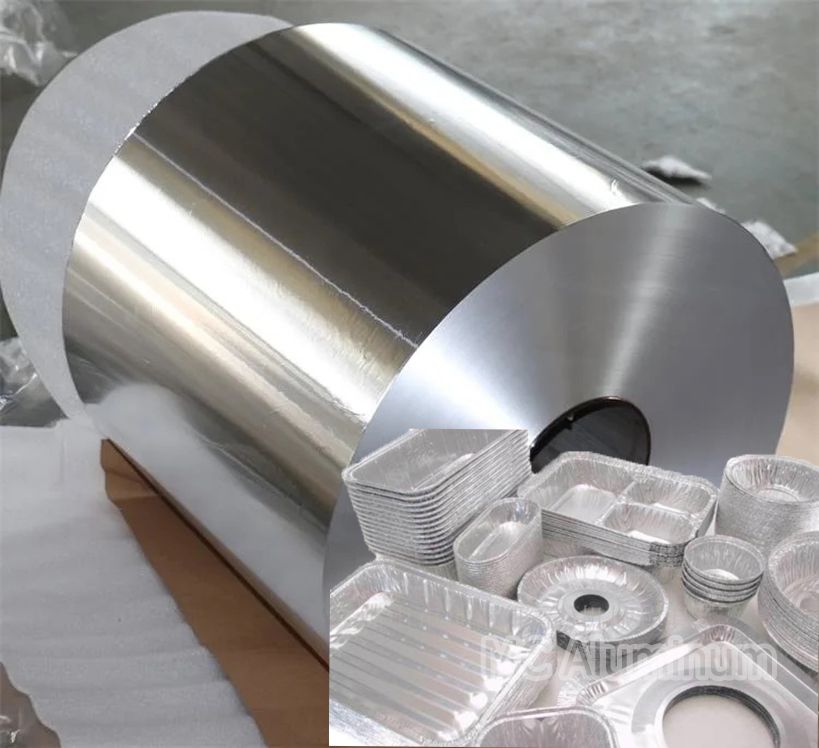

Fast food box aluminum foil is a thin sheet material made of pure aluminum or aluminum alloy. It plays a very important role in the catering industry. It is a widely used food packaging material. It is made of aluminum foil. It is a food-grade aluminum foil and is usually used. 8011 aluminum foil, 5052 aluminum foil, 3003 aluminum alloy, etc.

Lunch box aluminum foil specifications:

| Alloy | 8011, 8006, 8079, 3003, 3004, etc |

| Temper | O, H14, H16, H18, H19, H22, H24,etc |

| Thickness | 0.01-0.5mm |

| Width | 120-1600mm |

| Length | 10-16000mm |

| ID | 75/150mm |

| Surface | Polished, flat, smooth, stucco embossed |

| Application | food, kitchen, pharmaceutical, insulation, sealing |

Advantages of aluminum foil for fast food lunch boxes:

1.Good thermal insulation performance

Aluminum foil is thin and light and has good thermal insulation properties, which can effectively prevent the transfer of heat and maintain the temperature of food.

2. Efficient barrier performance

Aluminum foil has good anti-oxidation and moisture-proof properties, which can effectively maintain the freshness of food and extend shelf life.

3. Good processing performance

Aluminum foil can be processed and formed in a variety of ways and is suitable for a variety of snack packaging, baking and cooking purposes.

As an indispensable product in restaurants, aluminum foil lunch boxes have many advantages such as heat insulation, freshness preservation, pressure resistance, and high temperature resistance. Therefore, aluminum foil has become the preferred material for fast food lunch box manufacturers and has good development prospects.