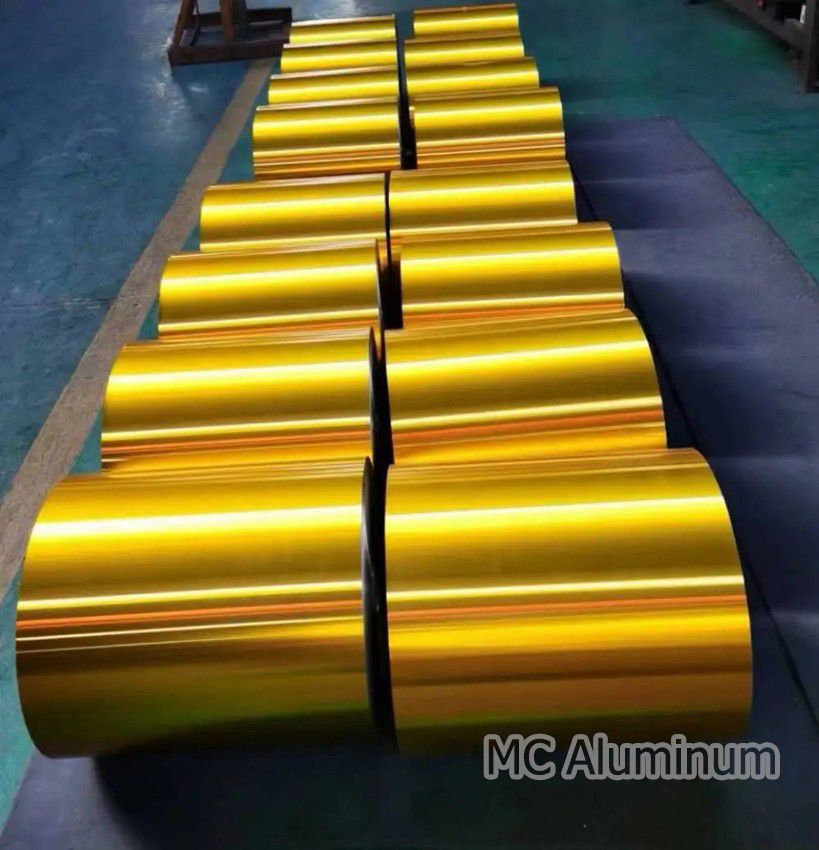

Coated aluminum foil is a coating material with good corrosion resistance and wear resistance. Coated aluminum foil is widely used in food packaging, pharmaceutical packaging, building materials, electronic products, aerospace and other fields. It can provide excellent moisture resistance, corrosion resistance, heat insulation, light insulation, anti-slip and other functions, which provides important guarantees for the performance improvement and extended service life of various products.

Common coating types include polyester, polyamide, polyethylene and epoxy resin, etc. Different types of coatings have different functions and uses.

Polyester coating (PE): commonly used in building decoration materials, with good weather resistance and UV resistance.

Polyvinyl fluoride coating (PVDF): strong chemical corrosion resistance, long-lasting color, often used in high-end building exterior wall materials.

Epoxy coating: has excellent adhesion and mechanical properties, often used in food packaging materials.

Acrylic coating: has excellent transparency and scratch resistance, suitable for home appliance housings and decorative panels.

Coated aluminum foil performance advantages:

1. Excellent barrier properties: effective moisture-proof, anti-corrosion, oxygen isolation, protecting the quality and safety of internal items.

2. Corrosion resistance: prolong the service life of aluminum foil.

3. Decorative: make the surface of aluminum foil have better visual effects.

4. Mechanical strength: enhance the wear resistance and tensile resistance of aluminum foil.

5. Conductive properties: some coated aluminum foils, such as coated aluminum foil, have excellent static conductive properties and can be used in electronic products such as batteries.

6. Increased functionality: waterproof, oil-proof, anti-static, flame retardant, etc.

Coated aluminum foil process flow:

Aluminum foil unwinding--cleaning surface--solution preparation--coating treatment (spraying, rolling)--drying and curing--baking treatment--quality inspection--rewinding and packaging