In addition to hydrophilic and hydrophobic coatings, air conditioner aluminum foil can also have epoxy coatings to improve durability and corrosion resistance. Epoxy coatings have strong adhesion and chemical resistance, and can effectively prevent acid and alkali substances and other corrosive media in the air from corroding the aluminum foil, thereby extending the service life of the air conditioner. Coated aluminum foil for air conditioners mainly uses 8011, 1100 and 3003 alloys.

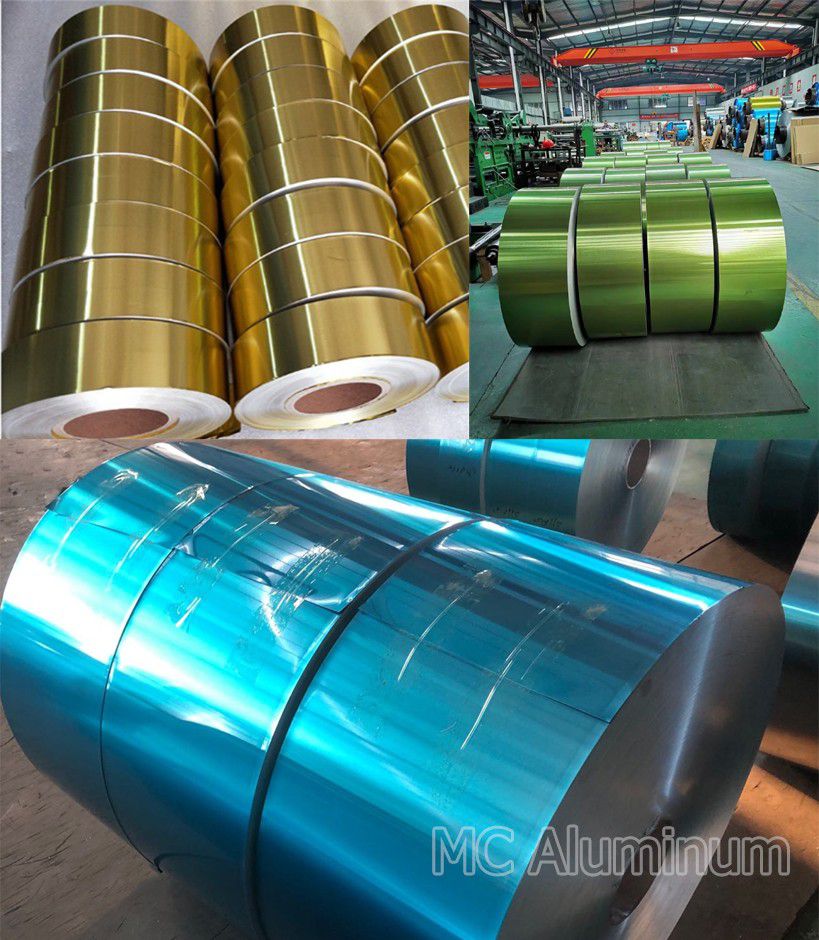

The hydrophilic layer is coated with color, which not only improves the aesthetics of the aluminum foil, but also provides differentiated identification for air conditioners of different brands or models. Common colors include:

1. Blue: Blue coating is often used for surface treatment to improve visual aesthetics while providing certain anti-corrosion protection. Blue coating can also help reduce the absorption of ultraviolet rays, thereby extending the service life of air conditioner components.

2. Gold: The gold coating not only looks high-end, but also has good corrosion resistance and can be used in more demanding environments. It helps reflect heat and improve the thermal efficiency of air conditioners.

3. Green: Green coating is mainly used in some special-purpose air conditioners, and can also provide better anti-corrosion and aesthetic effects.

Air conditioner aluminum foil specifications:

| Alloy | 1100, 1200, 3003, 8011, etc. |

| Temper | H22, H24, H26, etc. |

| Thickness | 0.07-0.2mm |

| Width | 200-1650mm |

| Inner diameter of foil roll | 75mm, 150mm, 200mm, etc. |

Advantages of hydrophilic coated aluminum foil:

1. Coated aluminum foil has good corrosion resistance and extends the life of air conditioning equipment.

2. It can be designed to be hydrophobic or hydrophilic, improve heat exchange efficiency and reduce noise.

3. It has antibacterial and anti-mildew properties, keeps the air conditioner clean and improves indoor air quality.

4. High temperature resistant, adaptable to stable operation under different environmental conditions.

5. Provide decorativeness and beautify the appearance of air conditioning equipment.

Why choose MC Aluminum?

1. MC Aluminum has introduced German Achenbach rolling mill and KAMPF slitting machine to produce aluminum foil. The products range from ingots to coils, with a maximum width of 1800mm and a minimum thickness of 0.006mm.

2. The company's aluminum foil products have ISO9001 and ISO14001 certificates.

3. The surface of the aluminum foil is free of pinholes, scratches, dents, oil stains, dust and other impurities, and the thickness is uniform.