Hydrophilic aluminum foil is a composite material with aluminum foil as the base material. It is hydrophilic treated through a special process and coated with a layer of hydrophilic coating on its surface. The coating models are mainly ordinary blue organic hydrophilic aluminum foil. It not only has the good heat dissipation properties of ordinary aluminum foil, but also has the corrosion resistance and hydrophilicity that ordinary aluminum foil does not have. It is a good heat dissipation material and is used in radiators of air conditioners.

It is more energy-saving to use blue-coated radiating fins for air conditioners, mainly because the hydrophilic properties of blue aluminum fins are very good. Simply speaking, hydrophilicity refers to the affinity between the surface of the air-conditioning heat-dissipating aluminum foil and water. It is generally measured by the angle formed by water droplets on the surface of the air-conditioning heat-dissipating fin aluminum foil. The heat dissipation of ordinary air conditioners is that the angle of water droplets on the surface of finned aluminum foil is above 70°, while the angle of water droplets on the surface of hydrophilic aluminum foil is below 35°.

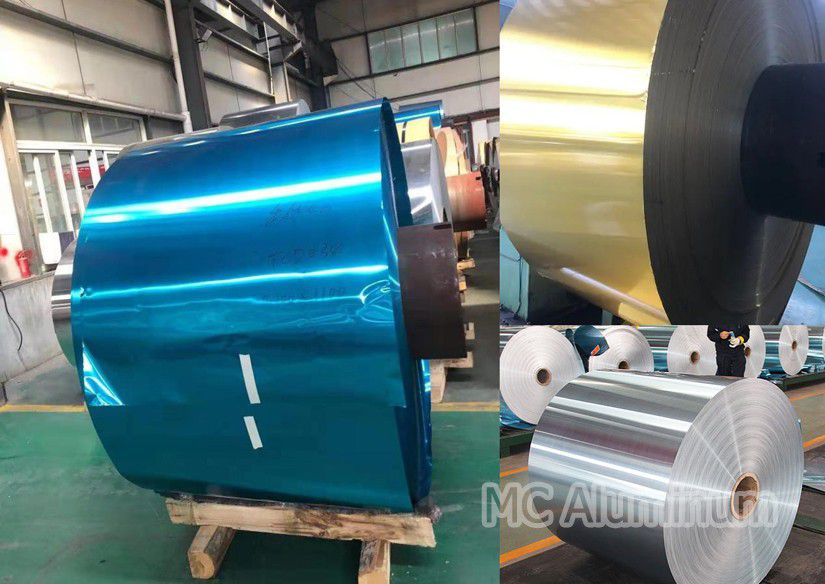

Hydrophilic aluminum foil specifications:

| Specifications | 8011/1100 |

| Temper | O/H18/H22/H24/H26 |

| Thickness | 0.08-0.2m |

| Width | 50-1600mm |

| Coil ID | 76,152 mm |

| Coating color | silver, blue, gold, etc. |

| Application | air conditioner, refrigerator, freezer |

| Samples available | |

| Packaging details | Fumigation-free wooden box packaging |

| Delivery details | 30-45 days after payment |

Advantages of blue coated hydrophilic aluminum foil:

1. It has strong corrosion resistance, improves the environmental tolerance of air conditioners, extends its service life, and improves the air quality in air-conditioned rooms. It can also maintain the hydrophilic properties of hydrophilic aluminum foil for a long time.

2. It has good processing performance and no mold wear.

3. The coating has good adhesion, heat resistance, water resistance, oil resistance, alkali resistance and reduces the wear of the punching die.

4. The air flow resistance is small, and the general heat exchange rate can be increased by 10%-15%.