Overview of 3102 Aluminum Alloy

3102 aluminum alloy belongs to the Al-Mn series anti-rust aluminum alloys. It contains manganese (Mn) 0.15-0.30% and iron (Fe) 0.2-0.50%. With excellent oxidation resistance, corrosion resistance, and formability, it is suitable for deep drawing, stretching, and other forming processes. It is widely used for air-conditioning heat exchanger fins, especially in outdoor condenser units, making it an ideal material for HVAC applications.

Tempers of 3102 Aluminum Foil

H18 (Full hard): Cold-rolled without annealing, very high hardness (tensile strength ≥180 MPa), low elongation (~1-3%). Suitable for applications requiring high rigidity.

H19 (Extra hard): Between H18 and H22 in properties; slightly lower strength than H18 but higher than H22; elongation ~2-5%.

H22 (Half hard): Cold-rolled and partially annealed, with moderate strength (tensile strength ≥120 MPa) and relatively higher elongation (~8-12%). Suitable for stamping and forming applications.

Performance Advantages of 3102 Aluminum Foil

1. Lightweight & Sustainable: Aluminum foil weighs only one-third that of steel and is 100% recyclable, aligning with sustainability goals.

2. Excellent Corrosion Resistance: Manganese in 3102 enhances corrosion resistance. A dense oxide film forms on the surface in humid or atmospheric environments, effectively protecting against oxidation.

3. Good Formability & Processability: H22 offers excellent ductility for stamping, bending, and laminating; H18/H19 provide higher strength for structural integrity.

4. Barrier & Sealing Properties: Aluminum foil completely blocks light, gases, moisture, and microorganisms, making it an ideal material for food and pharmaceutical packaging.

5. Electrical & Thermal Conductivity: Widely used for cable shielding and electronic heat dissipation, ensuring stable signal transmission and efficient thermal management.

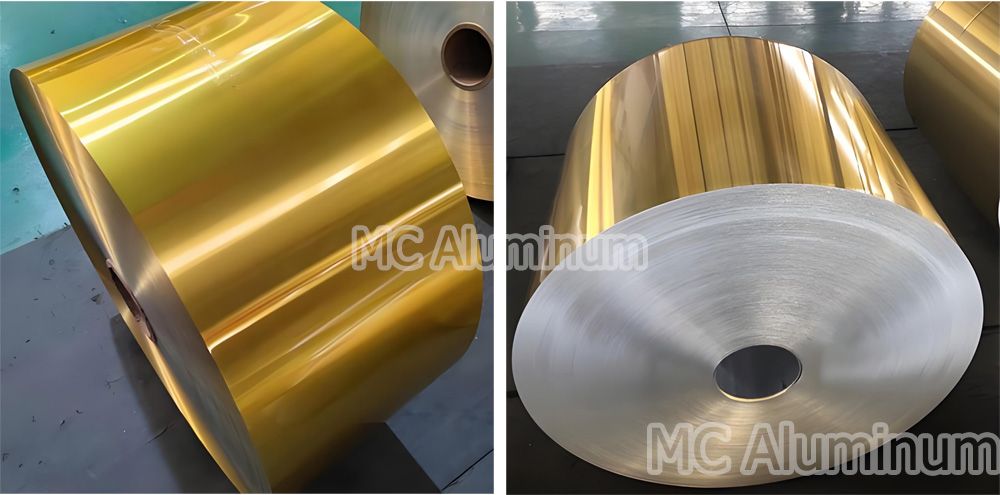

6. Aesthetic & Decorative Value: The surface can be anodized, color-coated, embossed, or laminated, offering higher decorative appeal and functional enhancements.

Product Information

| Alloy | 3102 |

| Designation | (AA) 3102, UNS A93102 |

| Tempers | H22 / H19 / H18, etc. |

| Thickness | 0.008mm - 0.2mm |

| Width | 250mm - 1650mm |

| Length | 100mm - 6000mm |

| Applications | Air-conditioning foil, hydrophilic foil, aluminum foil for heat dissipation, etc. |

| MOQ | 1-3 tons |

Chemical Composition of 3102 Aluminum Alloy (wt. %)

| Alloy | Si | Fe | Cu | Mn | Zn | Ti | Other:Each | Other:Total | Al |

| 3102 | ≤ 0.40 | ≤ 0.70 | ≤ 0.10 | 0.20 – 0.40 | ≤ 0.30 | ≤ 0.10 | ≤ 0.05 | ≤ 0.15 | Remainder |

Main Applications

Air Conditioner Heat Exchangers (Core Application): The most important use of 3102 aluminum foil is in the manufacturing of evaporators and condensers (commonly known as the “two devices”) in air conditioners. These fins require high strength to maintain shape, excellent thermal conductivity to enhance heat transfer, and hydrophilic coating to improve efficiency and prevent water droplet retention.

Other Heat Dissipation Applications: Also suitable for other electronic devices and mechanical components requiring heat dissipation.

How to Choose Between H18 / H19 / H22 Tempers?

Selection depends entirely on processing method and end-use performance requirements:

If extreme strength and rigidity are required, and subsequent processing is minimal, consider H19.

If high strength is required while retaining some toughness, H18 is a common choice.

If moderate bending or forming is required, and a certain degree of strength is required, H22 or H24 may be more suitable.