What is tape foil?

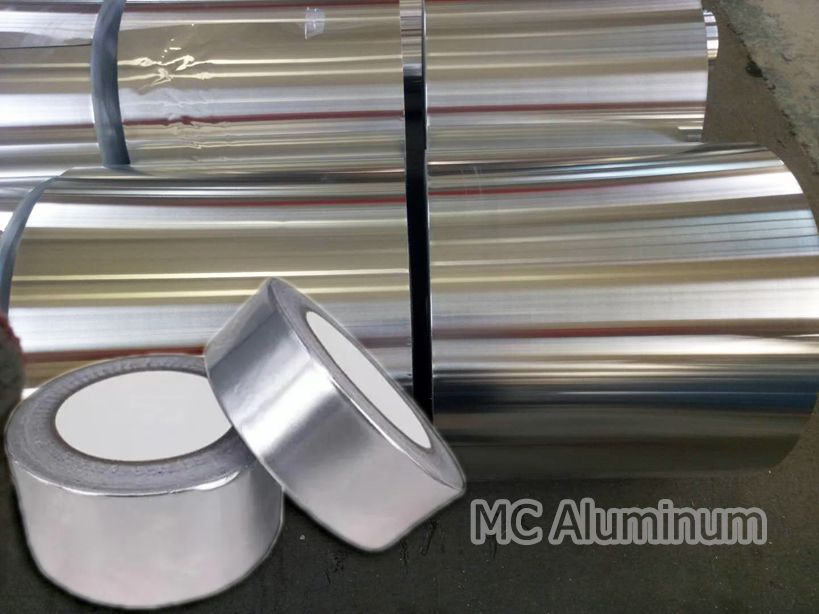

Tape foil is the raw material of aluminum foil tape. It is a light aluminum foil and needs to be coated with pressure-sensitive adhesive on the surface to be used as aluminum foil tape. The aluminum foil base material for tape is one of the raw materials in the production process of aluminum foil tape. It is a semi-finished product and needs to be processed before it can be used. The aluminum foil base material is made of 8011 aluminum foil, 1235 aluminum foil, etc., and is manufactured into aluminum foil tape through later compounding and gluing processes. It is an ideal supporting layer for the new generation of thermal insulation, heat insulation, sound insulation and other building materials.

The aluminum content of 1235 aluminum foil is not less than 99.35%, and it has excellent anti-rust properties, formability, weldability, heat resistance and high tensile strength. It is widely used in cables, tapes, and battery foils.

High-quality aluminum foil tape uses aluminum foil with an aluminum purity higher than 99.95%. Its function is to eliminate electromagnetic (EMI) interference, isolate the harm of electromagnetic waves to the human body, and avoid unnecessary voltage and current from affecting the function.

Tape foil has good coloring properties, high light and heat reflectivity, heat insulation, moisture-proof, sound insulation and other properties. Tape foil is used in refrigerators, air conditioners, automobiles, petrochemicals, bridges, electronics and other industries.