The cable foil is an aluminum-plastic composite foil made of aluminum foil (MC aluminum products) with airtightness and shielding properties, coated with plastic film on one or both sides, and used as a shield for the cable to protect the cable from damage. Corrosion and shielding models do not leak. Cable foil requires less oil on the surface, no holes, and higher mechanical properties.

Cable shielding foil is generally produced by 8011 aluminum foil, 1235 aluminum foil, etc.

Cable shielding foil specifications:

Alloy number: 1235, 8011

Material state: O, H22, H24

Thickness: 0.016-0.55mm

Width: 100-1600mm

Length: can be customized

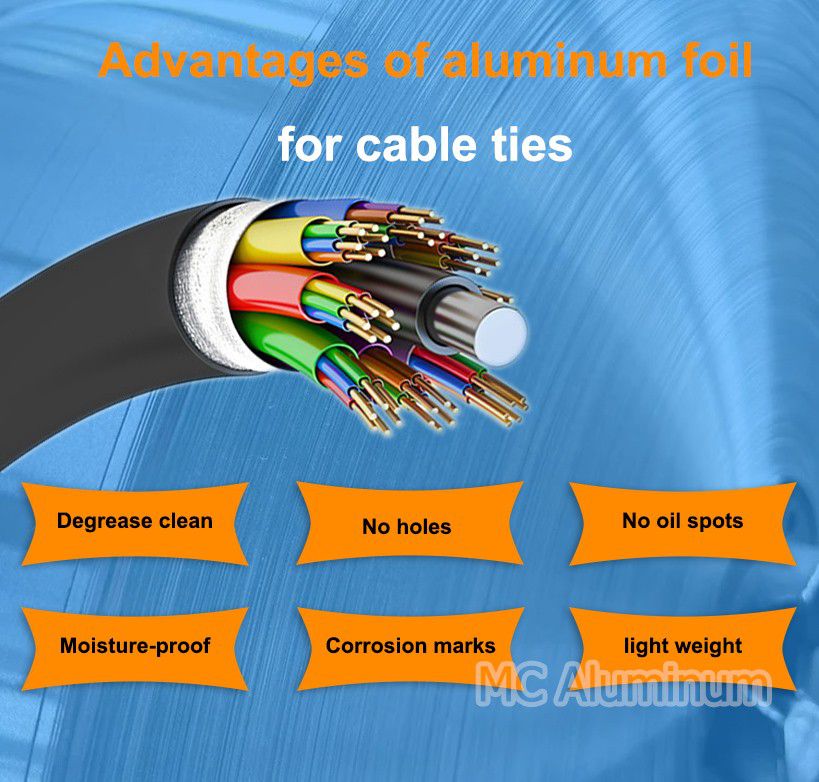

Advantages of cable shielding aluminum foil:

1. Small density, light weight, excellent oxidation resistance and corrosion resistance, not easy to corrode, and long storage time.

2. Good ductility, easy sealing, aluminum alloy has good bending performance, and its unique alloy formula and processing technology greatly improve flexibility.

3. Excellent insulation performance. The aluminum strip has the characteristics of excellent insulation performance, which can effectively prevent electromagnetic wave interference in the cable line and improve the transmission efficiency of the cable line.

4. The cable weight can be reduced, and the recycling rate is high, which reduces the installation cost.

Application of aluminum foil for cable ties:

After aluminum-plastic compounding, it is used to cover high-power cables and communication wires.

MC Aluminum is a large-scale manufacturer of aluminum sheet, strip and foil, specializing in the production of cable foil, with complete product models and high quality, which can be customized according to customer needs. The products are exported to many overseas countries and regions, and sample mailing services can be provided. Learn more about product information For more information and discounted quotes, contact us via email and the form below.