Insulation coated aluminum foil is a processed product that coats a specific material on the surface of aluminum foil to improve its insulation performance. This kind of aluminum foil not only retains the original excellent properties of aluminum foil, such as light weight, high strength, corrosion resistance, etc., but also obtains better insulation effect through coating treatment, while maintaining good thermal conductivity of aluminum foil.

Insulation coated aluminum foil usually uses the following aluminum alloys, and the specific selection depends on the application requirements:

1.1 series: 1050, 1060, 1100, etc.

Pure aluminum alloy, good thermal conductivity and electrical conductivity, suitable for occasions with low requirements for mechanical strength.

2.3 series: 3003, 3102, etc.

Contains manganese elements, with better corrosion resistance and strength.

3.8 series: 8011

Mainly used in applications such as packaging and cable shielding, with good comprehensive performance.

Insulation coated aluminum foil alloy grades:

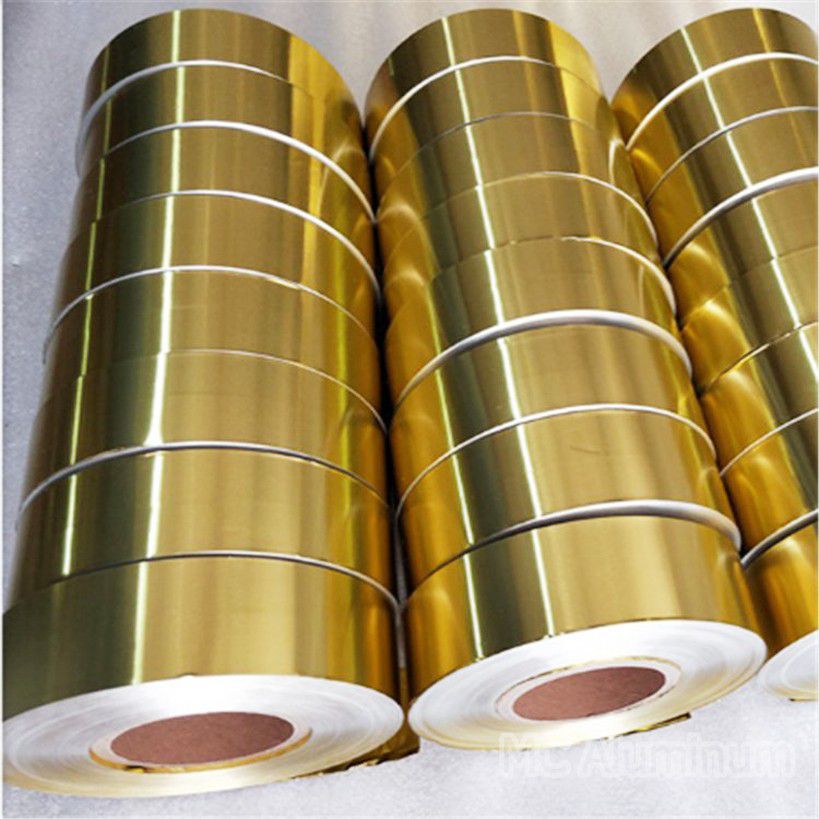

| Alloy | 1050 1100 3003 8011, etc |

| Temper | 0 H16 H18 H22 H24 |

| Thickness | 0.1mm-0.8mm |

| Width | 50mm-1250mm |

| Length | 100mm-16000mm |

| Inner diameter | 75mm/150mm/200mm/300mm/400mm/500mm. |

| Coating thickness | 5um-20um |

| Color | transparent color is the main color |

Insulation coated aluminum foil performance advantages:

1. Electrical insulation performance: The coating effectively isolates electricity, prevents short circuits and leakage.

2. Thermal conductivity: Aluminum has good thermal conductivity and is suitable for heat dissipation components.

3. Corrosion resistance: The coating is waterproof and moisture-proof, which enhances the durability of aluminum foil.

4. Light weight: Aluminum foil is light and has moderate strength, suitable for electrical isolation and heat dissipation.

5. Good processability: It can be cut, bent and formed, suitable for complex structures.

Insulation coated aluminum foil is widely used in the following fields:

Building materials: used as building insulation materials to improve the thermal insulation performance of buildings.

Electronic products: used for internal insulation and heat insulation treatment of electronic products to ensure the stability and safety of products.

Automobile manufacturing: used for heat insulation treatment of engine compartments, exhaust pipes and other parts in automobile manufacturing to reduce noise and temperature in the car.

Medical equipment: used in medical equipment for the manufacture of parts that require insulation and heat insulation, such as surgical instruments, medical equipment, etc.

Other fields: can also be used in aerospace, petrochemical, food packaging and other fields.

MC Aluminum, as a professional aluminum foil manufacturer, specializes in the production of 1xxx, 3xxx, 5xxx, 8xxx series aluminum foil. The product quality is high, and it can undertake 1-200 tons of orders. It is exported to more than 40 countries and regions overseas and is deeply trusted by customers.