Industrial aluminum foil has a relatively pure chemical composition and a thickness of 0.005-0.2 mm. It is not only moisture-proof, airtight, light-shielding, abrasion-resistant, fragrant, non-toxic and tasteless, but also easy to process into beautiful patterns and patterns of various colors because of its elegant silver-white luster. It is mainly used as capacitors, insulation materials, moisture-proof materials, etc. in the electrical and electronic industries. It can meet users' needs for large-capacity aluminum foil.

Industrial Aluminum Foil Production Process:

Raw Material--Casting/Hot Rolling--Rough Rolling--Intermediate Rolling--Finishing Rolling--Finished Product Annealing--Cutting--Packaging

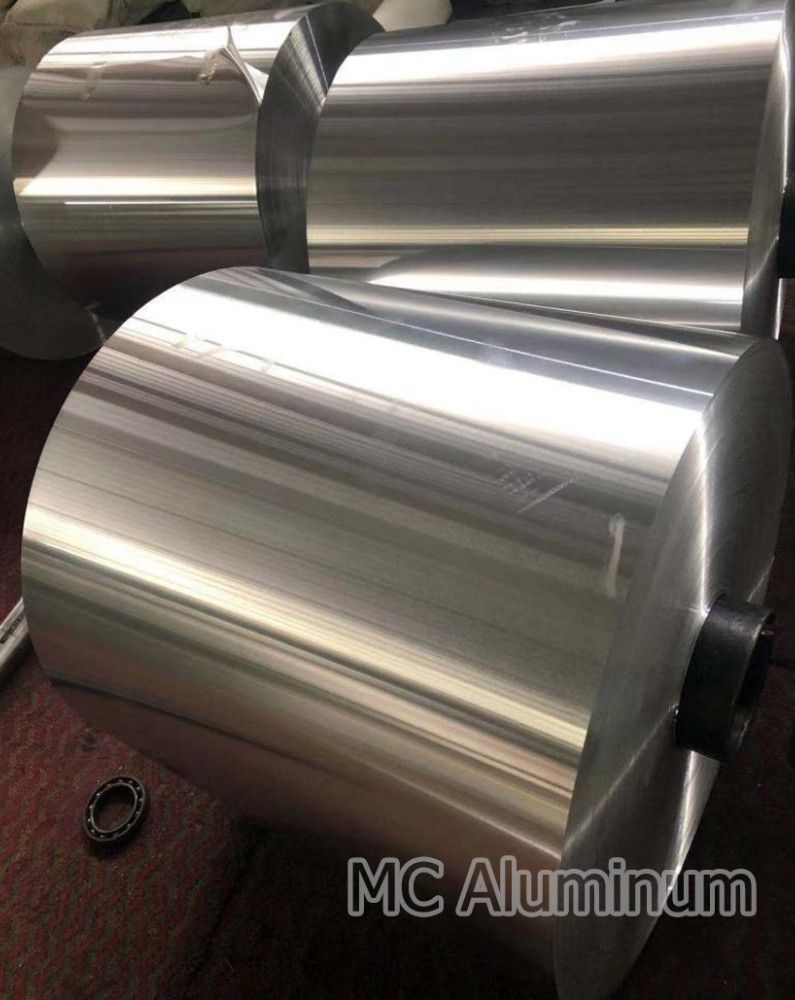

Industrial Aluminum Foil Coil Description:

Alloy: 8011-O

Thickness: 0.014mm

Width: 100-1600mm

Length: 100-16000mm

Exterior: Matt

Interior: Bright

ID: 152mm

OD: Min. 450mm, Max. 600mm.

Elongation: Min. 2%

Tensile Strength: Min. 80, Max. 130MPa.

Porosity: Max. 30 per square meter.

Wettability: A.

Joints: Max. 1 joint per coil.

Features of industrial aluminum foil rolls:

1. Usually made of high-purity aluminum or specific aluminum alloys to ensure excellent performance

2. Can be processed into very thin sheets with a thickness between 0.006mm and 0.2mm

3. Has high electrical and thermal conductivity, suitable for electronic and electrical fields

4. Has good corrosion resistance, suitable for a variety of environments

5. Lightweight, easy to transport and install, reducing the load in the application